Farm visit – The paradox farm: Stellar biosecurity, yet ASF emerged

As time moves on, many farms in Asia as well as Central Europe have had the sad experience of African Swine Fever visiting their farms. Often, something can be said about biosecurity being sub-optimal. But at the finisher farm of Pork & Co, 80 km from Bucharest, Romania – even for humans biosecurity levels are high. How did the virus ever manage to do it?

“This is it, compartment 11, pen 4. This is where it started.” Veterinarian Dr Adrian Balaban rests with both hands on the side of the pen wall. He stares at the 16 finisher pigs of roughly 50 kg which have stood up inside it. 32 eyes look back at him, totally oblivious of the fact that their pen was the place where African Swine Fever (ASF) was first detected, in August 2021.

It is easy to call it a paradox. On the one hand, it was no surprise at all that ASF occurred on the 9,600 head finisher farm, located at 80 km north east of Romania’s capital Bucharest, near the village Glodeanu-Siliştea. And on the other hand, it was as unlikely as it can be.

First of all – it was not a surprise because, of all countries in the European Union, Romania is likely the country that was hit the hardest with ASF. In a country where professionally integrated farms go together with backyard farming as well as a substantial wild boar population, the virus could spread very quickly. As long as the virus wouldn’t get inside the surroundings of the Pork & Co finishing barn, the site was safe. But when the virus emerged within a 3 km perimeter of the farm, the cause was lost.

Biosecurity practices

That the virus did manage to get in, however, was nothing short of a miracle. Dr Balaban, director of the Pork & Co cooperative as well as production coordinator, has had a keen eye for biosecurity. When ASF crept its way into Eastern and Middle Europe, he left no stone unturned to make sure that every possible entrance route got blocked and he devised a strict biosecurity protocol.

This started with the farm’s location – it is pretty isolated at the end of a rough country road of about 5 km long. Nobody goes here unless they have to be at this particular farm. Visitors who do arrive for a reason are not allowed to bring in any materials – even wedding rings, watches and photo cameras have to stay in the car at the gate, which is fenced off, with a stop sign and a disinfection bath.

Visitors walk in, sign a logbook, go through a Danish bench to change all clothes except underwear – and after a brisk 100 m walk to the farmhouse itself, a mandatory three-minute showering-in procedure follows. At this point, a completely new attire has to be worn, including a good pair of boots. Those are definitely needed, because at the beginning of every compartment, as well as every so often within the central aisles, trays are placed with the disinfectant GPC8 (glutaraldehyde), so the visit certainly is an on-going foot-dipping experience.

“I admit, I am obsessed with biosecurity,” says Dr Balaban, while putting some alcohol on his hands. Biosecurity is further enhanced by filtration systems in front of windows – even though the trees around the farm tend to block these, as well as a multitude of rodent traps encircling the building.

Regular security

Lastly – the farm is not only about biosecurity but also about regular security. Under Romanian law, premises have to be demonstrably protected to be insured against theft or robbery, which is why uniformed wardens patrol around the site, as well. The picture is clear though: one could say that a virus really has to do its best to get in.

The location of the outbreak within the farm is also a big question mark. Up until today, Dr Balaban and his colleagues have been puzzled as to how the virus managed to get in at the position where it did. It was not found in a far corner of the farm, anywhere close to an outer fence – no, it was found right in the heart of the farm, next to a sick pen. He says, “We had to send in samples as part of a general programme. We took blood whilst all looked normal. Then I think one came back with mild symptoms. By the Tuesday, only five or six were still alive – and soon after the rest was also dead.”

Dr Balaban sums up: “It could not have been the water – that is treated with chlorine, which kills viruses.” Puzzled, Dr Balaban concludes: “It had to be some kind of insect or rodent that brought it onto the farm.”

Be this as it may, the consequence of the discovery was harsh: a total depopulation had to happen, followed by a very thorough cleaning and disinfection round. Only then, very carefully, repopulation could follow.

Ambitious plan

African Swine Fever could have been the end of an ambitious cooperative plan of Pork & Co that had started in 2007 with 620 sows, and gradually grew into a complex of 11 farm sites with a maximum of 4,000 sows. But it wasn’t the end – as a new start was possible for the cooperative, consisting of a total of seven farm owning shareholders, with the aim to produce pigs at a level that is above market standards and with attention for animal welfare.

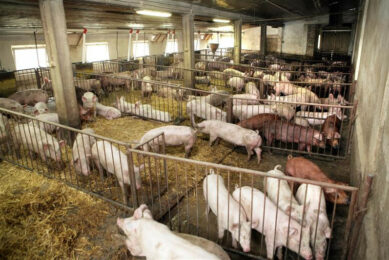

Pigs arrive at the finisher farm, called “Ferma de Purcei Buzău,” when they are about 65 days old (and weighing about 28 kg). The farm looks very clean from the inside, with pigs being calm, manure being frequently removed, pens equipped with up to five water points and even little windows so pigs can look at one another.

Each pen of 16 pigs has 2 feeders, by Groba and Rotecna, which can be operated by any finisher pig by pushing a bar which releases pelleted feed. Ventilation comes from under the aisles and air is removed through three chimneys in each compartment.

Romanian law

The pigs are sent to the slaughterhouse when they weigh roughly between 106 and 110 kg. This is all related to Romanian law – as animals heavier than 110 kg need more space, so it is convenient to bring them to the slaughterhouse just before that point.

The finisher pigs receive 3 rations of barley, wheat, corn, sunflower meal and soy, with rations changing every 25 days to contain lower protein levels each time, whereas fibre levels go up. The soy is all Romanian-produced, which is good for a premium. Even stronger – part of the Pork & Co cooperative is a relatively new soybean plant, where soybean meal is the main product and soybean oil is sold off as co-product.

The cooperative is trying to work together with its neighbours. Obviously, the feed plant purchases its inputs from its neighbours – and manure from the swine farm goes in the other direction.

In comes Comtim România

All in all, the ASF tragedy came at the price of about €300,000 in losses. So here was a decently functioning farm, with a good purpose, plan and management – yet the ASF-related market circumstances in Romania made continuation difficult. As exporting was no option anyway, Pork & Co sought the cooperation with Comtim România, which was operating as Smithfield România until early October 2024.

The integrator, which had a strong position on the Romanian market for decades, had always been supportive in purchasing part of the piglets and now stepped forward to make sure Pork & Co could pick up the production as part of the integrator. As a consequence, Comtim veterinarians started to look over Dr Balaban’s shoulder to align procedures. So, during the visit, Daniel Spiru, head of veterinary services at Comtim România, also joined in.

Dr Balaban says, “In the past, I could just make decisions I thought were right. Now I have to share my ideas with others, as well. And that is good.”

It is to be hoped, that biosecurity, a good plan and friends in high places will be sufficient to keep ASF out for good. After all, the virus hasn’t disappeared yet from Romania.