The feed price crisis – Part 1. What you should do

For several reasons, prices for animal nutrition have gone up drastically over the last months causing many pig producers all over the world and especially Europe to face difficult times. In this two-episode series, pig management expert and Pig Progress columnist, John Gadd, presents a broad spectrum of ways how to save money on pig feed.

By John Gadd

Since the autumn of 2007, much higher feed costs have increased the cost of production (COP) by between €0.30 to €0.50 per kg liveweight. In the more developed European pig industries, even before the feed price increase, food costs were 75 to 80% of variable costs and 50% of total costs, and are now proportionately higher still.

For that reason, the question is: how long will this serious situation continue? Due to world demand and for various reasons, cereal prices look set to be very high, at least until the harvest of 2008. Before then it is inevitable that some pig and poultry producers will quit their industries. This will have an effect on pig prices as pigmeat becomes scarcer.

Already there is evidence of a rise in the region of €0.06/kg liveweight, but it would be unwise to predict more than double this by early summer The feed price crisis For several reasons, prices for animal nutrition have gone up drastically over the last months causing many pig producers all over the world and especially Europe to face difficult times. In this two-episode series, pig management expert and Pig Progress columnist, John Gadd, presents a broad spectrum of ways how to save money on pig feed. 2008. This leaves a huge mountain to climb and unless wheat prices ease, this still provides a €0.24 to €0.37 shortfall. How might hard-pressed pig producers narrow this gap at little or no cost?

Here is a list containing some suggestions:

- Keep searching for cereal alternatives, especially locally. These may still be around. For unfamiliar products like sorghum or milo, always try to buy on dry matter expectation and consult with a pig nutritionist regularly who can formulate daily nutrient intakes and check for anti-nutrient factors, etc.

- Keep a close eye on feed price trends and buy more feed on forward contract if feasible, so as to lock in any price advantage.

- Buy more feed at one time, after checking you have sufficient dry storage, especially with others on a group basis to negotiate a better price, as this eases the storage and transport costs of the supplier.

- Sell pigs sooner. Later weight gain is inefficient in food use. Use a computer model (many pig nutritionists have them) to establish a current weight threshold – for example, at present in the UK industry 90 to 95 kg looks beneficial, but this can change as pig sale contracts are renegotiated. It is as important to watch European pigmeat prices as it is feed prices.

- Seek leaner genetics. Initially these may not necessarily cost more and chosen well in relation to lean meat output, better lean gain genetics are always cheaper because they increase income for the same or less feed cost/ pig, meat being largely made up of water.

- Reduce feed wastage. This is a universal problem and serious because its extent often goes unrecognised by producers. About 6% is common and not appreciated on nearly every farm I visit. Farmers think about spillage, but there are five other ways of wasting food besides spillage. About 2% feed wastage is achievable if all of them are taken into account; 1% drop in feed wastage equals 1% better FCR. The difference between 6% and 2% is worth a huge 9.6 cents/kg.

- Improve early health – weaning to end of nursery especially. So in a crisis, do continue to use the veterinarian and check again on your batch cleaning routine as many producers are way out of date with the latest trends. Reducing post-weaning mortality by 1% cuts COP by 1.3 cents/kg.

- Re-evaluate feed additives. A confusingly large number have come on the market since AGPs were banned and some are/may not be cost effective compared to other nutrient options, e.g. adding fat, when energy costs have risen so steeply. One authority says that in his opinion only 4% of growthenhancing additives are now justified in this crisis. Talk to a pig nutritionist about how he/she might prefer to use the cost of some feed additives in other more direct, nutritional ways.

- Improving growth rate by 50 g/day reduces COP by 1.9 cents/kg. With winter here, temperature, overstocking and ventilation will be the main growth rate restrictors assuming nutrition is correct. Each of these individually can account for 30 to 40 g/day less. Check all these with an adviser (and for the environmental aspects with an engineer, as calculations will be involved).

- For example nursery ventilation is often excessive (vets love fresh air!) and minimum ventilation rate is frequently set at 20% when only 5% above capability is needed. This saves power costs of 1.6 cents/kg. If in doubt, consult an engineer.

- Minimise moving and mixing. One mixing move costs at least a day to slaughter (three days if done badly). Just one day adds 5.1 cents/kg to COP.

- Sow output has a major influence on COP. An extra pig born alive per litter cuts COP by 8.8 cents/ kg. Making time for more attention and vigilance at farrowing can produce this result on its own, as can more Attention to correct timing of AI service based on the predicted length of each sow’s estrus from past experience. Look again at this underused management record.

- Turning off lights in a typical growing/ finishing room this winter for 12 hours when you would normally have them on (pigs need only dim light to see troughs and drinkers) can save up to €1.60. Install one dimmer switch per building and if you have, say, 20 rooms occupied for 18 weeks, this will save 0.03 cents/kg on every finisher.

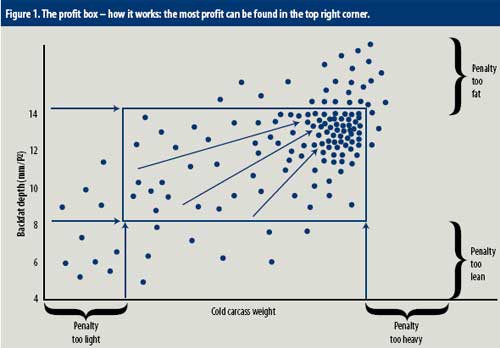

- Achieve maximum contract weight targets, as the highest price thus obtained is multiplied by more pigmeat sold. If you are not already doing so, operate the ‘Profit Box’ graphical system for each batch of finishers sold; see also Figures 1 and 2.

This has three important advantages:

- It shows you at once how close each shipment was to your target

- By overlaying other contract ‘boxes’ on offer it shows you which of them might better ‘fit’ your normal performance with a view to changing – or renegotiating your present one.

- If your genetic sources are labelled within the box it shows the progeny from which boars/ semen are doing you proud as well as identifying those less profitable. The latter can be drawn to the attention of your genetics supplier, and to your nutritionist who then has information to adjust daily nutrient intakes if needed.

15. A fourth advantage is that it encourages your staff to know what your contract weight

targets are and how to achieve them.

Now let us look at what a few of these actions can claw back on the cost of production, see Table 1. As shown, these figures cover the present shortfall, as mentioned in the beginning of this article. Of course producers will not be able to make all these savings in COP – it is not that ideal a world – but if a little help of, say, a further 6 cents/kg was to come from the retail sector, then at least it would give some encouragement to help producers ride out even the severity of this latest storm. And relieve some of the deep anxiety they feel at the present time.

In a following article, some ‘emergency’ actions will be listed, which producers are tempted to take based on past experience of profit crises, and why they are most unwise.

Finally, producers are going to have to apply for extra finance to sustain cash flow so as to last out the depression. Again, based on plenty of past experience of negotiating with financiers, guidelines shall be set out on what lenders look for from applicants when times are tight. They cannot lend to everybody and these notes will give you a better chance of being ahead of the rest.