Olmix consortium opens first algae plant in Brittany

On the eve of SPACE 2013, feed additives manufacturer Olmix has opened the first ever algae biorefinery plant near the commune of Plouénan, in northern Brittany, France.

The official opening was conducted last Monday. Over 150 attendees from all over the world attended a special four-day inauguration programme, between 8 and 11 September, which combined presentations and lectures as well as leisure elements.

The plant has been constructed by Olmix and four other industrial partners from Brittany in a consortium named Ulvans – an acronym for ‘Ulves Valorisation Nutrition Santé’. It also includes two French research centres, the University of South Brittany and CNRS of Mulhouse.

Olmix focus on algae from seaweeds as they provide a rich source of nutrients, also very useful in pig and poultry production. Algae are rich sources of minerals, polysaccharides and proteins.

The company points to the fact that in recent years an increasing number of publications have demonstrated the relevance of seaweeds in numerous biological mechanisms, par¬ticularly in the immune response. In many cases, the company continues, the role of the sulfated polysaccharides in the interaction has been demonstrated, as well as the importance of the sulfate groups.

The algal polysaccharides are recognised to influence the immune system by a vast number of pathways.

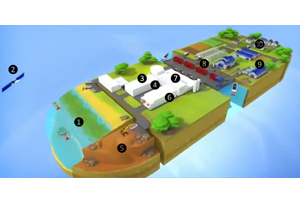

Inside the biorefinery plant, precise steps are followed to ensure all ingredients are extracted from the algae. Numbers correspond to the image.

1. Harvesting algae – Collection from boat, collection in shallow water from the beach.

2. Satellite tracking sheets of seaweed – Facilitates the geolocation for collection from boat.

3. Pre-processing the algae – Washing, grinding.

4. Extraction of active molecules – Enzymatic hydrolysis for the release of active ingredients from seaweed without solvent (first molecules for animal and vegetal health), centrifugation (purification), drying.

5. Clay extraction – Second essential natural product: Montmorillon’s clay recognised for its quality and stability.

6. Pre-processing the clay – Crushing, drying, grinding ball and dynamic selection to obtain superfine clay and optimise the interaction with algae but also the action in the digestive tract.

7. Formulations based on natural products for animal and plant health and nutrition: Amadéite: Incorporation of seaweed extract in the interlayer space of the clay to develop new active ingredients in parallel to a research laboratory with the beneficial properties of algae (antiviral, anti-inflammatory, anti-cancer)

8. Finished products for different markets: Melspring (vegetable crops in greenhouses and orchards); PRP (open field cultures); Olmix and Amadéite (animal nutrition, hygiene and health)

9. Aquaculture – Replacement of fish protein with sustainable solutions such as algae.

10. Applications – Exportations