New standards to reach the magic number 30

Water, sun, air, feed and of course pigs – no element is forgotten when planning and constructing the newly built sow facility at Beel family farm, in Wortegem-Petegem, Belgium. The ?mix of novelties should lead to improved production too.

By Vincent ter Beek

Pig producer Joost Beel, 53, and his wife Mieke Beel-Steyvaert, 51, have no doubt. Before the expansion, their pig farm’s productivity was at a respectable 29.5 piglets per sow per year – but once the new additions are fully operational, the productivity of their farm will break that magic boundary of 30.

Speaking in mid-December 2013, the couple is lucky enough to be able to set new standards for themselves. In times of an ongoing financial crisis and ever-growing environmental and animal welfare concerns, pig farming has become top sport in Belgium just like anywhere else in Western Europe. Nevertheless, with their son Pieter-Paul, 20, interested in farming as well, farm continuation is guaranteed for another generation so investing would not be a jump in the dark.

Beel family farm added a large new sow house – the farrow-to-finish farm thus growing from 150 sows to 480, a tripling of the sow capacity. In addition, the existing grow-finisher barn was extended by 28 metres to a total of 68 metres.

Next step will be the transformation of what used to be the sow facility into a nursery. As from 2014, the farm’s capacity will be 2,000 grower pig places (until 25 kg) and 1,600 finisher places. A fourth, existing building, was transformed to be used as a quarantine facility for young gilts.

Pioneering

The farm is located in relative isolation, as it is about 40 km east of Roeselare, which is considered to be the heart of Belgium’s pig production area. Previous expansions had already made Beel family farm one of the pioneers in pig production. In order to continue to be on the forefront, and also to meet the latest requirements with regard to environment and animal welfare, the farm was in need of another upgrade in 2013. Implementing novel technologies was taken into account from the very first designs.

With 480 sows, the new sow house has space for eight groups of gestating sows, of 48 animals each. In addition, there are two farrowing rooms, also for 48 sows.

Group housing

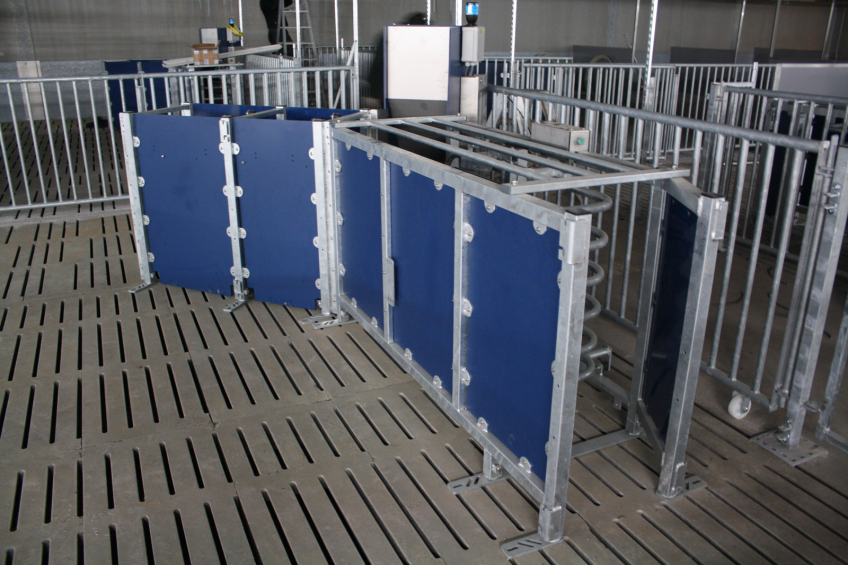

Not surprisingly, and just like any other facility in the European Union, Beel family farm had to comply with the group housing directive in the EU. Having come into effect on January 1, 2013, the directive states that all sows must be kept in group housing during gestation. Since the construction works were underway, the farm was given dispensation during last year. Unlike many in Belgium, Beel family farm opted for Electronic Sow Feeding (ESF) rather than free access stalls. The farm is one of the first worldwide to have Fidos ESF stations, designed by Belgian feeding equipment manufacturer Roxell.

The Belgian company recently entered the market with this design, which allows for up to two different types of feed to be fed. Sows can get different rations of the ingredients for their needs depending on age, parity and gestation phase.

The Roxell system comes without doors – and it was this which was important for Joost Beel: “Doors in my opinion cause restlessness among the sows,” he says. Instead, the Fidos ESF station is designed with an open door concept, this makes it very easy for all sows to enter the ESF system. Stealing leftover feed from the previous sows is prevented by the through valve, which closes off the trough.

Slopes

The gestating sows can rest in compartmentalised sections which are slightly sloped. “Sows like it like this, they will usually lie head-down,” explains Joost Beel. “The concept works pretty well, as should there be any excrement in the laying zones, then it will simply flow lower due to the slope and disappear through the slats.”

Ceiling ventilation

Ventilation is a story in itself in both new sections of the farm. The gestating sow house is equipped with so-called roof ventilation. This system became a viable option as the gestating sows are housed in large, open, 33 m wide spaces with no objects or walls blocking the air flow. The idea is that air is being drawn in above the ceiling at the pig house’s front, over the farrowing area and then released from the ceiling through little hole-punched metal sheets above the sows’ heads. The air will take a U flow through the area until it disappears again through the chimneys.

The ceiling ventilation leads to a different lighting design, as TL tubes cannot be hung to the ceiling. These are now attached to the pen furniture, rather than to the ceiling.

Snout ventilation

Where fresh air is coming from above in the gestating sow house, lactating sows benefit from air coming from below. Here, the air drawn in will follow a different path made just above the manure pits. It is released through slats in the aisles between the crates, thus rising up and circulating near the troughs and the sows’ snouts. This way, the sows are ensured of fresh, relatively cool air as they prefer a lower temperature than their piglets.

Piglet nest heating

The piglets, however, prosper when their environment is being kept warm – for them, apart from a lamp, a heated floor section is provided inside the farrowing pen. This non-slatted floor part is heated by water inside, which has been warmed up by a heat pump and a heat exchanger just behind the air scrubber – more about this later.

Avoiding crushing

Included in the construction of the farrowing pens is the Balance Frame concept – an innovation by Nooyen Flooring Systems. This system protects the neonatal piglets from being crushed by the sow in case she would decide to lie down suddenly. When she raises, her back touches a sensor, activating a lifting mechanism, effectively elevating the sow’s floor several centimetres above the piglet level. This way they cannot enter her zone. As soon as the sow lies down again, the mechanism performs the opposite function and will lower the sow to piglet level again, allowing perfect teat access.

Heat exchanger and air scrubber

The expanded facility as well as the new facility both have been equipped with an air scrubber. These are placed in an addition at the top level of the farm house. Air is first drawn away from the pig rooms through chimneys – the farm house’s entire attic thus functions as a long wind channel.

When about to leave the farm house, the air is first drawn through a heat exchanger. In this system, the air flows through a maze of tiny tubes with water. The air’s rest warmth rises the temperature of the water. This water, then having a temperature of 18-20°C, is subsequently sent to a heat pump, after which the water at 35°C will heat the piglet nests in the farrowing rooms.

Back to the outgoing air: Having gone through the heat exchanger, the air is also scrubbed by a mixture of water and bacteria, thus reducing up to 90% of the outgoing air’s amount of atmospheric particulate matter as well as ammonia.

Energy use

The desire to be relatively independent from oil or other sources of fossil fuel is present in more features. Beel had solar panels added to the roof of the new additions. On top of that, the space between the new sow facility and the expanded finisher house was covered with a roof too, also covered with solar panels.

The total amount of solar panels thus was created to be 5,000 m2, which in summer should make the facility entirely self-sufficient, energy-wise.

Water use

Also with regard to water, the farm aims for self-sufficiency. Large amounts of roof also allow for the ‘catching’ of rain water, which is carefully stored in two underground basins underneath this same space between the two buildings. In addition, water is pumped up from ground water level. Water quality up to drinking level is ensured by filtering using highly porous volcanic lava. The total combined storage facility of this rain water and drainage water is about 900,000 litres.

Other features

Beel family farm will endeavour to keep the sows in either farrowing or gestating areas – the insemination room will only be occupied very shortly. Since piglet embryos are moving towards the uterus as from day four post-insemination, sows should not be moved back into group housing between roughly day 4-5 and 25.

Beel says, “We will do a pregnancy check in the group housing.”

Last but not least – the future 30+ piglets per sow per year will go to the grow-finisher places, in the expanded 68 metre facility. The existing part is used to house growers and is completely revamped and equipped with e.g. the Blu Hox Plus feeder equipment, also by Roxell. When in full operation, distinguishing between old and new will be a job for the trained eye.

For more pictures, please check www.pigprogress.net

Beel-Steyvaert farm, Belgium

Farm type: Mixed farrow-to-finish farm

Size: 480 sows; 2,000 grower places; 1,600 finisher places

Piglets/ sow/ year: 29.5*

Feed conversion rate: 2.2/ 2.3*

Average Daily Gain: 780 g* (finishers)

Genetics: Topigs 20 (dam line); Piétrain (sire line)

Pre-weaning mortality: 19%*

Vaccinations (sows): Parvovirus, erysipelas, E. coli, atrophic rhinitis

Total farm surface: 55 ha

Other crops: Wheat, beetroot, potatoes, maize, beans, grass seeds

* These performance figures were achieved prior to the farm’s expansion.

Source: Pig Progress magazine Vol 30 nr 1, 2014