Natural notions save energy and time

Herd expansion on Jørgen Christiansen’s farm in Havndal, Denmark, presented an opportunity to replace the sow stalls with a system that respects consumer demands for welfare. Jørgen’s final choice for natural ventilation and sow groups with electronic sow feeding (ESF) stations has also answered his own demands for an economical production system.

By Anabel Evans

Jørgen Christiansen switched from sow stalls to group housing more than 18 months ago, at the same time as the farm’s herd size was increased from 200 to 800 sows. The new system is designed inside two large, naturally ventilated buildings – one for breeding and the other for dry sows. As Peter Hansen from Skiold-Echberg explained, “In the late 1990s, we started to discover why large naturally ventilated buildings became too cold during the winter period in Denmark.” Jørgen is certainly very pleased with the climate conditions inside the dry sow house – no unpleasant ammonia odour – and stable temperature levels in the summer and winter of 19ºC and 17ºC, respectively.

The 80 x 26 metre dry sow house has four separate groups of around 140 sows each. The group size was chosen for easier management – Jørgen’s own preference. On either side of the central passageway the pens have a slatted concrete feeding, dunging and drinking area adjoining 6 x 6 metre solid concrete floor nest boxes. The lying pattern is very predictable – all in a line – and no problems with dirty pens.

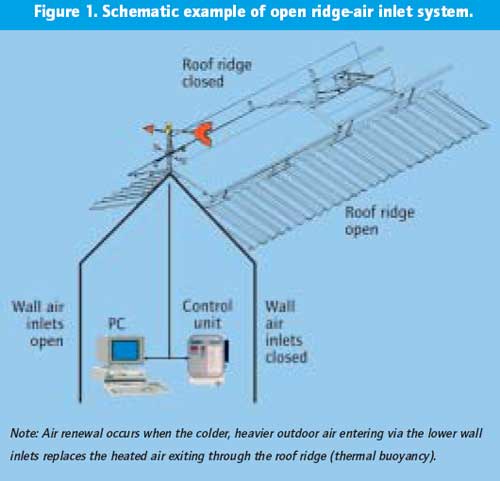

Peter Hansen said, “In buildings of this size, the automated natural climate control programmes used to close the side panels and leave the roof ridge open when temperatures dropped.

This is actually wrong – you have to close the roof ridge and vary the side panels depending on the wind speed and direction.” A weather station positioned on the roof and connected to the control unit ensures that the inlets and roof ridge are adjusted in line with the changing weather conditions (Figure 1). The fact that the running energy costs for the building are zero with no electricity necessary for fan operation, Jørgen was prepared to invest an extra €4,000 in this system. He is also pleased with the choice of lighting plates in the ridge section, providing some natural light in the building.

Skilled stockman for daily check

Sow groups are introduced into the ESF system immediately after insemination. Jørgen was keen to emphasise that this has not created any problems in terms of performance. Aggression in the groups is not seen as a problem; he sees that any newly introduced group tends to live as a subgroup and can always easily be found in the same nest box.

Once per day during the weekdays the most experienced stockman walks through the pens adding a handful of straw. He uses this moment to carefully check that all the sows are mobile and in a good and similar condition. This is estimated to take one hour. If there is any suspicion of a problem, the hand terminal is used to identify the sow and her data can immediately be reviewed, e.g. feeding level, days into gestation. Changes to the feed, or following day separation from the group for further treatment, can be made via the hand terminal. Feeding times are arranged to suit the working routines on the farm. A new day starts at 22:00 hours and finishes at 09:30 hours. Sows have adapted to feeding during the night so that in the morning any sows selected out (automatically) will be ready for staff to take them to their next destination, e.g. farrowing rooms. The feeding ration is based on 100 g of liquid feed every 30 seconds with sows tending to eat their daily ration in one visit and taking about 20-30 minutes. Jørgen’s preference for only 47 sows per station is based on the fact that he believes it is important to give the sows time to eat. He says, “There is too much stress in the group if each sow is forced to eat quickly. They organise themselves into regular, relaxed eating patterns.” The feeding stations are closed from 14:00-22:00 hours to bring some peace into the house and it also helps to deter the dominant sows from continually walking through the feeders.

Attitudes changed all-round

The same number of staff (four) work on the unit as before but Jørgen recognises that they have much more time to concentrate on the details of management rather than the general must-do routines, e.g. feeding, cleaning out. For example, the slatted section in the gestation barn is cleaned, but on a rotational basis with around 15 minutes per week allocated to this task. After more than 18 months Jørgen feels very comfortable with the system. In fact he is learning to manage rather than be part of the hands-on working team and has participated in a manager and motivation course. He uses an Agrosoft Windows management programme, which he admits takes time to start up initially because of all the required data input, but once this is completed numerous analyses can be made and time behind the computer settles down to around one hour per day.

The sows have also changed their attitude since being housed in a group system. They are said to be more relaxed in the presence of staff and more inquisitive. Most positive is that they can be moved and handled in a stress-free manner; they walk from themselves and are not scared. The farrowing process also occurs with less intervention required from staff; born dead averages 1.1 piglets compared to 1.5 with the old stall system.

Patience important to training task There is one important routine specific to this system that does require time and patience – the training of gilts and sows. The staff use a separate pen specially allocated for this task where the tactic of feed reward is used for gilts entering the station.

Training is carried out for 3-4 weeks before the first insemination. In the new breeding barn, also with natural ventilation, the weaned sow groups are moved into large straw bedded pens with feeding stalls on either side. Jørgen again is very pleased with the system. The stalls are used not only for feeding but also to lock the sows in during the insemination period to make it peaceful. The Thursday weaning of 50/60 sows is followed by Tuesday morning AI with a second insemination 24 hrs later. The weaned piglets are taken to a separate site nursery for 6.5 weeks and then sold at 27 kg. The farrowing rate with the new system is 89/90% compared to 85% before. Boar stations in the ESF pens are used to help detect sows returning to heat. An estimated 6% of returns are detected via the boar detectors and 6% during the routine scans at 4-5 weeks. The farm policy is to cull all returns and the herd has a 50% minimum replacement rate.

Time for improvements

Directive details In 2001 the EU adopted a new Pigs Directive, which prohibits sow stalls as from 2013. The tethering of sows was banned by the 1991 Pigs Directive and comes into force in 2006. Under the new Directive, the sows must have permanent access to straw or some other manipulable material, and part of the floor must be solid; from 2013 each sow must be given at least 1.3 m2 of continuous solid floor and each gilt at least 0.95 m2. The total minimum space allowance for sows and gilts in groups from 2013 is 2.25 m2 and 1.64 m2, respectively. These provisions apply to existing farms from 2013 and for new farms from 2003. Another requirement from 2003 is that pregnant sows must be given enough bulky or high-fibre food to satisfy their hunger. |

While it should not be underestimated how much management energy is required to introduce a new production system, in Jørgen’s case switching from stalls to groups fed via ESF stations, his satisfaction and enthusiasm about the changes were very evident. The capital investment came to €1,000 per sow but the same number of staff not only manage a larger herd but also have more time to concentrate on production details. For example, Jørgen is particularly keen on the management of feeding in the farrowing pens. Staff are encouraged to check and optimise feed intake, increasing feed levels whenever they can, certainly on a daily basis. He says that it is proven that a 10 kg loss in sow live weight over the lactation period can cause 0.5 piglets less in the subsequent litter. The farm has a 10% pre-weaning mortality (2% crushing) and here again a major objective is to reduce this to 7%.

For the future Jørgen mentioned his ambition to increase the herd up to 1100-sows and add a third location to his two-site system to grow the weaners on to slaughter weight.