Mexico bounces back from H1N1

Mexico’s swine production continues to move ahead in terms of consolidation, expertise and production levels. The industry in Mexico has now largely recovered from the consumer concerns, media scares and mis-information surrounding the 2009 pandemic human strain of influenza pH1N1 California strain. At present Mexico is seeing its pig operations move ahead, with exports in demand.

There are currently around 1 million sows housed in Mexico, with strong domestic and export markets. The backyard farm sector is largely confined to southern areas, with central and northern farms running on commercial farm system models, often with two- or three site, multi-site production. There is increasing integration (breeder and feed suppliers, finisher contractors) around the major cities and the export centres in the north-west Sonora region.

Agribusiness operations in Mexico are often run as a mix of pig farms, layer chicken egg farms around a strong feed mill supplier, with beef and sheep populations also kept as on-site free-range livestock. Relatively high feed input prices are currently countered by good farm-gate prices. The high price and uncertain availability of corn (imported and local) for animal feed, is often countered by the use of feed-grade sorghum placed into pig rations.

Guadelajara

Near the agricultural centre of Tepatitlan city, the Grupo Gigante farms is located – a well-run 5,000 sow, multi-site swine farming operation in central Jalisco province. The farms provide around 100,000 finisher pigs each year into the local Guadalajara markets (Mexico’s second city). This farm system also has several chicken egg layer operations nearby.

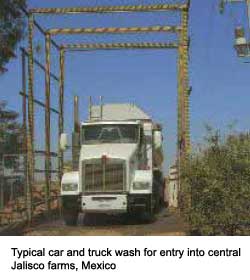

The farms planned for and embraced good biosecurity and management control of operations, with well-separated facilities for breeder, nursery and finisher pigs. There are separate on-site staff and delivery trucks for each phase of the operations, with excellent car and truck washing facilities (see Photo). All trucks and cars are kept separate from pig housing, via on-truck boom cranes for feed delivery etc. All staff shower when entering and leaving pig sheds. The farms have a closed herd, with both females and semen derived from one major commercial supplier. The managers and veterinarians are actively investigating new improved lines of semen from other suppliers, aiming for some hybrid vigour in their genetics.

Finishers

The finisher sheds was constructed in a typical 800 to 1,000 head capacity in a set of eight week-by-week sheds. Each shed has excellent curtain-sided ventilation and water-filled flush gutters for cooling. While American strains of PRRS were present on farms, the closed farm structure had led to stable infections and low finisher mortality rates of only 1% to 3 %. Pigs were fully vaccinated with international vaccines for PCV2b and Mycoplasma. They were planning the use of the Enterisol ileitis vaccine to control some diarrhoea and poor performance in the finishers.

Mexico has a poorly regulated farm medicine sector, with low barriers to market entry. Therefore many generic medications of variable quality are available and farmers and veterinary advisors must take care to differentiate price and quality.