Managing Variation at Slaughter by using a ‘Profit Box’

“ Some variation is largely unavoidable – but manageable!” (Dr. John Patience, 2008). This last year I seem to have visited more farms than usual where this problem was raised. The problem of variation in shipping weights resulted in under-occupied pens holding up the re-occupation of the finishing building with new pigs. I’m sure you have noticed it, but housing costs as a percentage of real-term total costs (outside inflation) of raising a finishing pig have nearly doubled in the past 20 years, especially for new-builds. Empty pens waste capital resources.

©On 7 farms visited recently, re-occupation was delayed as long as 14 days, and allowing for 1 day clean-down and 2 days drying out, this 11-day lag reduced gross margin per pig by 4 % (range 2-11%)

©I tackled it in this way……

©

©1. ©Establishing the current situation.

We checked each farms position from their processors’ returns for each batch shipped against their market target. In terms of overweights, underweights and carcase achievements (grading/probe results).

©

©

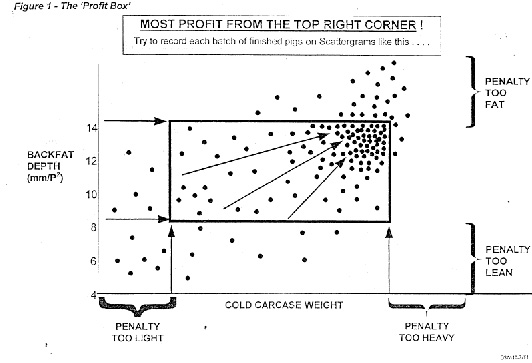

2. The ‘Profit Box’ (Use 1)

©©We put every batch thus analysed into this Profit Box system to appraise the situation graphically. Three were already using the concept (but not fully, see later) but four were not. My diagram explains the idea.©Everybody should be putting each shipped batch though the box – I’ve been saying this for years. It gives you a continuous check on where you are in your shipping skills – absolutely essential.

©

3. The Profit Box (Use 2)

The position of the sides of the box are dictated by the terms of your marketing contract with the processor. Different contracts have different shaped/different sized boxes, some being more ‘lenient’ than others. Producers should be continuously checking that as many of their pigs as possible fit into the box.( ie. their current contract) and located towards the top right hand, maximum income corner This comparison is vital whenever an existing contract’s terms ©are modified, or an alternative choice of contract appears from elsewhere. This is done by placing the new or altered contract’s box lines over your current/ historical achievements and see which one encloses the most pigs. 85% is the minimum for an efficient unit today, with at least 66% into the top right-hand quartile.©

©

The monetary payment you will get from the percentage of pigs enclosed in the box will guide you to which contract is likely to be the best to suit your typical/expected performance. It is important to do this calculation as, for instance a ‘lenient’ box could pay you less for your pigs inside their box than one which might exclude more overweights/underweights/grading failures – but pay you more for those which do get in.

©

©4. The Profit Box (Use 3). Best done on a computer.

©If each pig in the batch is flagged with details of its genetic source, especially from its male lines, then a good check can be kept on the value any boars or AI semen used. From my own experience it is quite surprising how such differences show up quickly – not only the number of finishers getting into the box but also how many gravitate to the top right-hand corner and which boars/AI semen are the leaders in this respect.

©

©Next blog. ©Having adopted a system which gives you a good chance of success in revealing the extent of variation at slaughter, in my next blog I will suggest what are the six primary causes of liveweight variation (and which you can do something about) which reduce the likelihood of too many finishers not getting into that vital top-right potential profit corner.

©

Concentrate on these six and you are well away!

©

©