A model to adapt pig buildings to climate

Hotter summers and colder winters can both impair pig production. As a result, pig house designs which once used to be suitable are now being questioned. Adaptations in terms of barn structure, equipment and management need to be evaluated. In the PigSys project, IFIP and INRAE scientists developed a model-based tool for such multicriteria evaluation.

Ambient conditions (temperature, hygrometry) have a major influence on grow-finishing pig performance. Due to genetic selection for leaner animals with reduced appetite, pigs are increasingly sensitive to ambient temperature outside their thermoneutral zone.

Under cold temperatures, pigs use some dietary energy to regulate body temperature at the expense of growth and feed efficiency. Exposure to hot temperatures induces a decrease in feed consumption and growth rate, even more so under wet conditions.

Pigs are reared indoors to mitigate outdoor condition effects on performance. However, climate conditions are changing; for instance, heat waves were observed repeatedly in late spring or summer in the last few years. These episodes impaired performance and increased loss rates. Technical choices for barn configuration need to be revised. Equipment, insulation and regulations are questioned for both existing and new buildings. Changes in technical choices and management have to be proposed and evaluated regarding criteria such as technical and economic performance as well as energy consumption.

Simulating impacts of technical choices

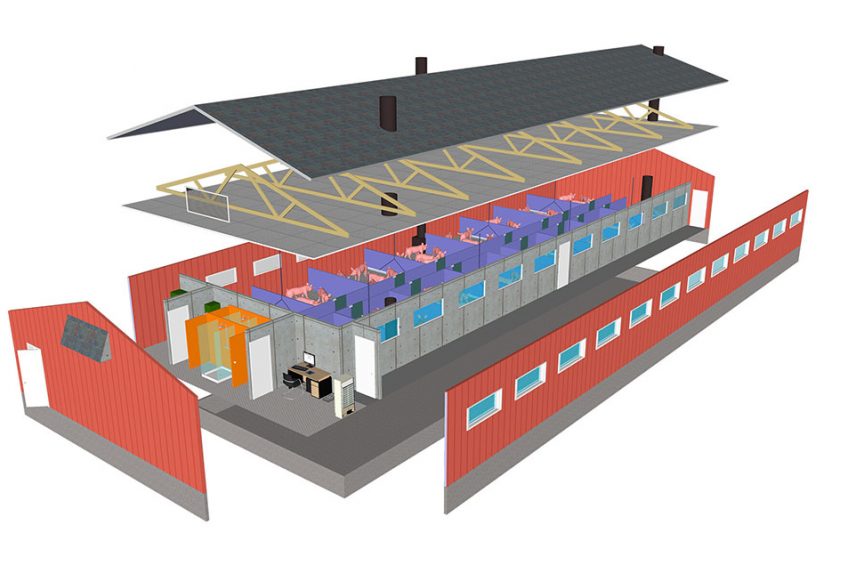

Combinations of wall insulation, available equipment, regulation rules and pig management strategies are too numerous to evaluate well on-farm. Therefore, the tool “ThermiPig” was developed. This modelling approach virtually represents the functioning of a finishing room and of a group of pigs reared indoors. ThermiPig allows the dynamic simulation of room thermal balance depending on outdoor climate conditions, room characteristics, regulation rules of climate control boxes and management of pigs. It is then possible to evaluate the consequences of indoor conditions on finishing pigs’ performance, nutrient excretion into the environment, electric power consumption, etc. and to perform multicriteria reporting allowing comparison of various technical sets of options.

ThermiPig is merging two models. On one hand, the InraPorc model, originally designed by the French National Institute for Agriculture, Food and the Environment (INRAE) to simulate pig growth under thermoneutral conditions; on the other, the bioclimatic model ThermiSim, designed by the French Pork and Pig Institute (IFIP), that allows simulation of the thermal balance at the room scale depending on incoming air characteristics and heat produced by pigs or equipment or lost due to air renewal or through walls.

Different modules

ThermiPig is organised in different modules that represent the finishing room in compartments dynamically connected to each other. Information describing room dimensions (height, ceiling area), floor type, wall insulation and number of places is gathered in the module “Room”. Installed equipment (fans, heaters, pad cooling, etc.) and their regulation rules are described in the module “Equipment”. The module “Management” allows description of maximal occupancy duration of fattening room, management of delivery to slaughter house, feed allowance and sequence, nutritional characteristics of diets and pig characteristics.

Once the modules have been populated, ThermiPig is used to simulate the ambient temperature each hour, depending on the growth stage of the pigs and the outdoor climate conditions. It is easy to demonstrate the great value of heaters when outdoor temperatures are very cold and pigs do not produce enough heat to balance the losses (typically at the start of growing period). ThermiPig can also evaluate pad cooling, especially under very hot outdoor conditions when pigs produce a lot of heat (typically at the end of the finishing period).

Like any other decision-support tool of this type, the goal is not to predict exact pig performance (even if this ability has been verified using experimental data obtained in IFIP facilities). The aim is rather to be able to compare diverse combinations of equipment, feeding strategy and room characteristics.

Illustration on the effect of indoor temperature

Figure 1 and Table 1 illustrate how the indoor temperature changes during five days in the growing period, with seven different settings for the climate control box of fans, in parallel with variations of outdoor temperature.

For each setting, the average performance obtained by simulation on several batches of virtual pigs are compared: growth performance of pigs, margin over feed cost, nitrogen excretion, direct (electricity) and total energy consumption (including energy due to total feed intake). The most interesting setting is selected based on a colour code as illustrated in Table 2. In the present case, the setting n°5 shows the best compromise on all criteria. This setting does not allow growth performance to be maximised (which is the case for settings 1 to 4, with green coloured cells), but it allows better results to be reached for all other criteria (white coloured cells) and it therefore warrants more study.

ThermiPig is associated with a data warehouse platform developed by the Latvia University of Life Sciences and Technologies, with a user-friendly interface that facilitates entry of inputs (based on farm data, or predefined examples) required to run the model. It can be expected that ThermiPig can be used as a basis to develop a decision-support tool that could help stakeholders assess the sensitivity of pig farms to climate change.

This research was part of EU project PigSys – Improving pig system performance through a whole system approach.

* Authors Quiniou and Marcon are attached to IFIP-Institut du Porc, France; author Brossard is attached to INRAE (French National Research Institute for Agriculture, Food and Environment).

Authors

Dr Nathalie Quiniou, Michel Marcon and Dr Ludovic Brossard