Maximising farm value by enhancing biosecurity measures

In animal farming, the practice of cleaning and disinfecting farm environments encompasses not just routine hygienic measures but serves as a crucial strategy to mitigate infection risks at the farm level.

Enhanced biosecurity promotes healthier animal populations and supports a reduction in antimicrobial use within the animal health sector. There is a significant correlation between the thoroughness of the cleaning process and the health outcomes observed in farm animals. An effective cleaning regimen not only aids in achieving desired health results but also contributes to the overall economic efficiency of farm operations.

Defining efficient cleaning

Efficiency in cleaning activities is principally achieved through the application of scientifically formulated detergents compounded with water. These detergents rely on the multifunctionality of surfactant molecules, which are amphiphilic in nature—possessing both hydrophilic (water-attracting) heads, which may be polar or charged, and hydrophobic (water-repelling) tails that amass non-polar contaminants. Surfactants are classified into four categories based on their ionic charge characteristics and cleaning properties:

- Non-ionic surfactants exhibit neutrality, low foaming tendencies, and are adept at emulsifying and eliminating organic contaminants.

- Anionic surfactants display a negatively charged head, possess robust foaming capabilities, and are versatile in soil type management.

- Cationic surfactants have a positively charged head, and they often fulfil roles in antistatic applications.

- Amphoteric surfactants, possessing dual charge potential, are adaptive molecules that can behave as cationic or anionic agents contingent on the pH environment.

These surfactants are essential for their ability to diminish surface tension and enhance product penetration. Given the high levels of soil often encountered in the animal health industry, detergents with superior penetration capabilities are indispensable for efficiently lifting and removing tenacious debris. Such efficiency translates into appreciable savings in time, energy, labour, and water usage.

Depending on type of surfactants, detergents will have a faster micelle creation and also foam capacity, and together with pH value, a detergent will perform with a very special behaviour.

Kenosan is a highly effective alkaline detergent, specially formulated to tackle the robust challenges of cleaning animal manure.

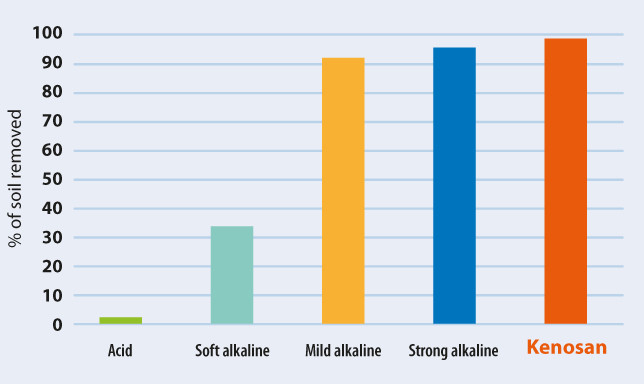

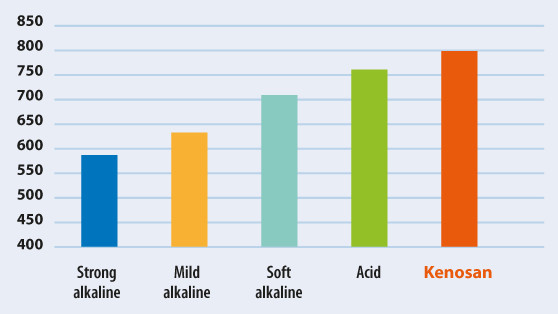

In the comparative trial performed by CIRLAM laboratory, it is demonstrated that an optimally performed cleaning procedure should achieve more than 90% of soil removal, and in this case, the alkaline detergent compared to their main competition, showed the highest cleaning removal on a very sticky and grease soil (soil beef grease and pork brain) when diluted at 1% with a contact time of 15 minutes action (Figure 1).

Figure 1 – Cleaning efficacy of product diluted in 1% tap water. Contact time 15 mins. Soil beef grease and pork brain.

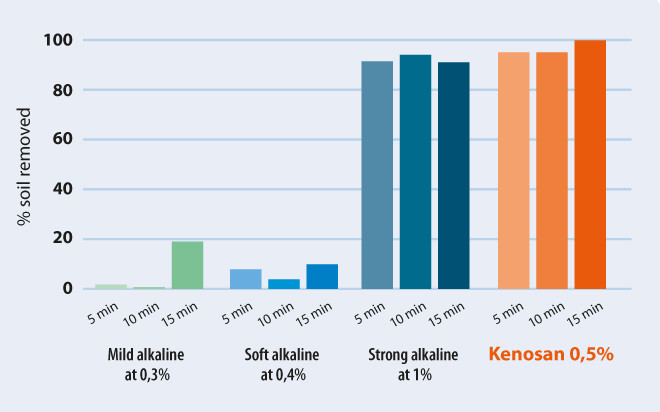

In the same comparison trial, all products were diluted at minimum registered dosage and analysed at 3 different times: 5, 10 and 15 minutes.

Kenosan, at 0,5% dosage, showed outstanding results on the same soil type (beef grease and pork brain) demonstrating once more its strong efficacy and efficiency (Figure 2).

Figure 2- Cleaning efficacy comparison of products diluted at minimum dosage, following the guidelines mentioned in the product’s technical date sheet. Soil type: Soil beef grease with pork brain. All products were tested at different time: 5, 10 and 15 minutes.

Microbial reduction and disinfection

As previously mentioned, an optimally performed cleaning procedure can effectively remove over 90% of microorganisms in a given area, preparing the environment for an effective disinfection phase.

Ideal disinfectants can achieve a log 5 reduction of bacterial populations, indicating the necessity of reducing microbial levels to below 100,000 CFU/cm² during the cleaning step to effectively eradicate pathogens and attain optimal disinfection conditions.

Monitoring ATP after cleaning process can be an important tool to ensure cleaning efficacy and prepare the surface for the next step: the disinfection process.

Quantifiable savings

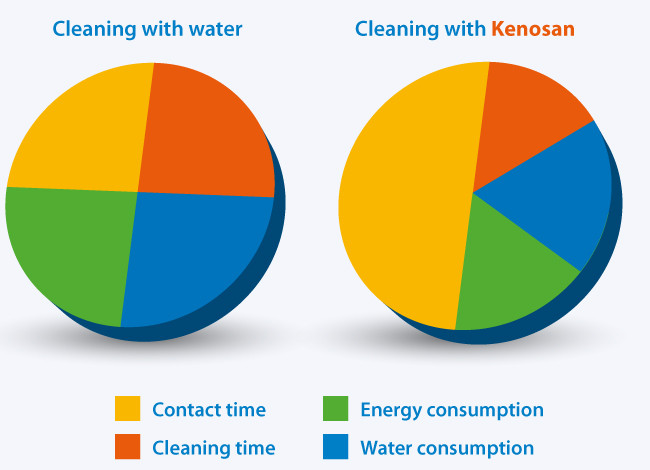

Despite the prevailing use of water and mechanical force for cleaning in animal houses, this traditional method demands considerable water, energy, and manual labour.

Kenosan supposes a modest investment in an effective detergent formulation resulting in a 40% enhancement in cleaning efficacy relative to simple water-based cleaning, while concurrently reducing water consumption by up to 30% and labour time by up to 24% in industries like pig and poultry farming.

The detergent’s foaming performance is also a critical metric, as higher foam quality may reduce chemical usage while extending contact time, thus ensuring more robust adherence to varied surfaces.

At the comparative trial performed at CIRLAM laboratory, the alkaline detergent showed a foam capacity 35% more effective than that of leading competition. A well-chosen detergent, therefore, represents a substantial return on investment in terms of resource efficiency and cost-effectiveness (Figure 3).

Figure 3 – Foam creation in ml performed by SITA foamer tester R-2000. Products are tested at 1% dilution in tap water with 250ml volume sample stirred during 20 seconds at 2000 rpm at 20oC.

Conclusion

Investment in specially formulated and efficient detergents, such as Kenosan, is justified by tangible benefits including a 24% reduction in cleaning time-frames, significant water savings, and disminution of energy and manual labour requirements. These investments lead to a 40% improvement in cleaning results, thereby elevating farm hygiene and enhancing internal farm biosecurity. This boost in biosecurity is fundamental to comprehensive disease management on the farm, portraying cleaning and disinfection as pivotal operations with far-reaching impacts on animal product and animal health.

References are available on request.

Comparison trials performed at CIRLAM laboratory are available on request.