A deep dive into liquid feed hygiene

Liquid feed is a playground for yeasts, moulds and other bacteria. It provides the perfect environment for them to grow. Hygiene is key in liquid feed systems. So how can producers ensure good liquid feed hygiene?

In Europe, liquid feed is particularly popular for swine in northern and western countries — including Denmark, the Netherlands, Ireland, Belgium, France, Germany, Italy and Sweden — where a huge proportion of finishers (more than 70% in Denmark, France and Ireland) and sows are fed liquid feed.

Liquid feed is made by mixing cereals and minerals with water and sometimes also with co-products of the human food and beverage industry. Liquid feed can be associated with lower costs, improved feed intake, increased palatability and better animal growth.

Why is hygiene crucial in liquid feed?

Liquid feed provides the perfect environment for yeasts, moulds, lactic acid bacteria and enterobacteria to grow. Hygiene is key in liquid feed systems to maintain good pig health. The goal is to limit the growth of undesirable microorganisms and manage bacterial biofilms in the system, which helps decrease the risk of contamination.

Hygiene is also important to preserve the feed’s nutritional quality. When mixing the dry feed ingredients and co-products with water, spontaneous and uncontrolled fermentation by the microbes present in the cereals or in the environment can occur. These microbes will use nutrients from the feed — making them unavailable for use by the pigs — and can even produce toxic compounds (e.g., biogenic amines), which deteriorate the quality of the feed and may be harmful for the animal.

Additionally, good feed hygiene influences feed efficiency. In sows, for example, better hygiene in liquid feed is expected to increase milk production thanks to improved feed utilisation, leaving more energy available for milk production. Ensuring the sanitary quality of liquid feed and the feeding system itself is a key priority for raising high-quality pigs.

Take a look at this video about good farming practices: microbial ecosystem of liquid feed

How can producers ensure liquid feed hygiene?

Ensure good quality raw materials

Little is known about the microbiological quality of cereals. The composition of the microbiota present on the cereals is determinant for the liquid feed quality and its evolution in time. Depending on the balance between positive and undesired microbes, the nutritional and sanitary qualities of liquid feed can be degraded. Performing regular analysis on raw materials will help decrease the risk of contamination of the liquid feed.

A study conducted in 2017 gathering 66 samples of cereals across Europe demonstrated the ability of the specific microbial inoculant Pediococcus acidilactici CNCM I-4622 to positively affect the microbial profile of different types of cereals when mixed with water.

Adopt proper cleaning procedures

The surface of the tank and pipes are usually coated with biofilms. These are complex structures containing the microbes and their matrix that protects them. Biofilms are difficult to remove. When biofilms contain pathogenic bacteria, they can be detrimental to liquid feed quality and animal health. Adapted cleaning protocols can help manage biofilms inside the liquid feed system. A complementary strategy consists of using a specific microbial inoculant able to support the establishment of a positive biofilm.

Using a specific microbial inoculant

The lactic acid bacteria strain Pediococcus acidilactici CNCM I-4622 which was already marketed as a zootechnical feed additive with benefits on performance for piglets and fattening pigs, has recently been authorised in the European Union as a technological feed additive, in the categories of acidity regulator and hygiene condition enhancer for any type of liquid feeds. This lactic acid bacteria has been recognised for its potential to reduce pH and limit growth of coliform bacteria in liquid feeds, offering an effective tool to help ensure liquid feed hygiene and quality.

A recent study, presented at the Pig Research Summit, monitored the acidification and hygiene enhancing properties of this specific microbial inoculant in pig liquid feed.

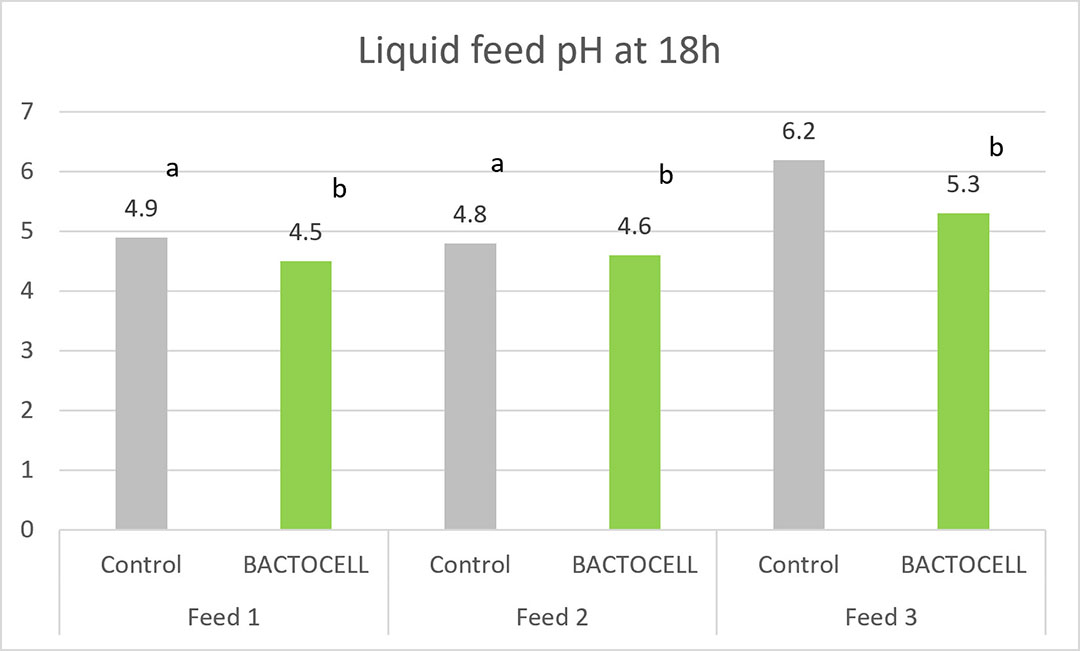

After 10 hours incubation at 30°C, the feeds containing P. acidilactici CNCM I-4622 were better and faster acidified than control feed. Feed pH remained significantly lower for up to 24 hours (Figure 1). Similarly, the concentration of L-lactic acid in the feed was significantly higher with the lactic acid bacteria.

Figure 1- Effect of P. acidilactici CNCM I-4622 on liquid feed pH at 18 hours (n=3 feeds).

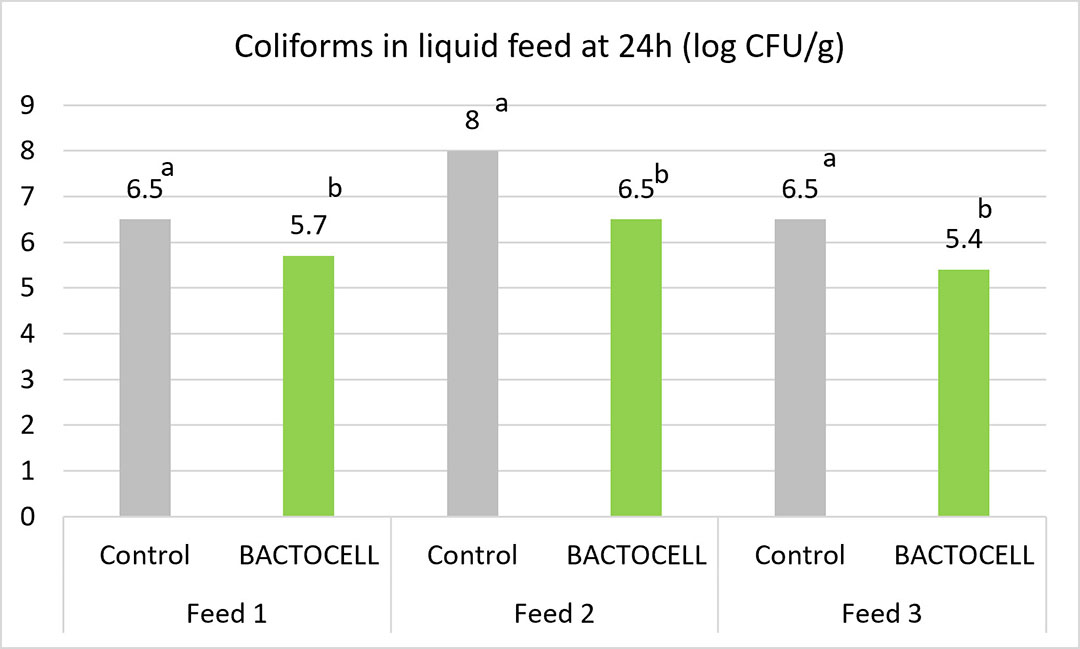

This enhanced lactic acid production ensured better feed hygiene as indicated by the significantly lower total coliform counts (Figure 2).

Figure 2- Effect of P. acidilactici CNCM I-4622 on liquid feed total coliforms count at 24 hours (n=3 feeds).

Jacobs C., Hupé J.F., Pélissié I., Demey V., Saornil D., Bravo de Laguna F., Castex M. 2023 Potential of liquid feed hygienization by Pediococcus acidilactici CNCM I-4622 (MA 18/5M) to improve milk production. Pig Research Summit 2023, Copenhagen, Denmark.

The researchers concluded that P. acidilactici CNCM I-4622 acidification properties contribute to the improved hygiene of pig liquid feed by reducing the development of total coliforms.

For more information, please visit www.lallemandanimalnutrition.com

Not all products are available in all markets nor associated claims allowed in all regions.