Controlling piglets’ microbial environment

Every time new pigs enter a barn, biosecurity measures impact the level of infection pressure. Integrating a biofilm approach has been shown to be an effective tool to complement these measures, by helping to install a positive microbial environment after the disinfection step.

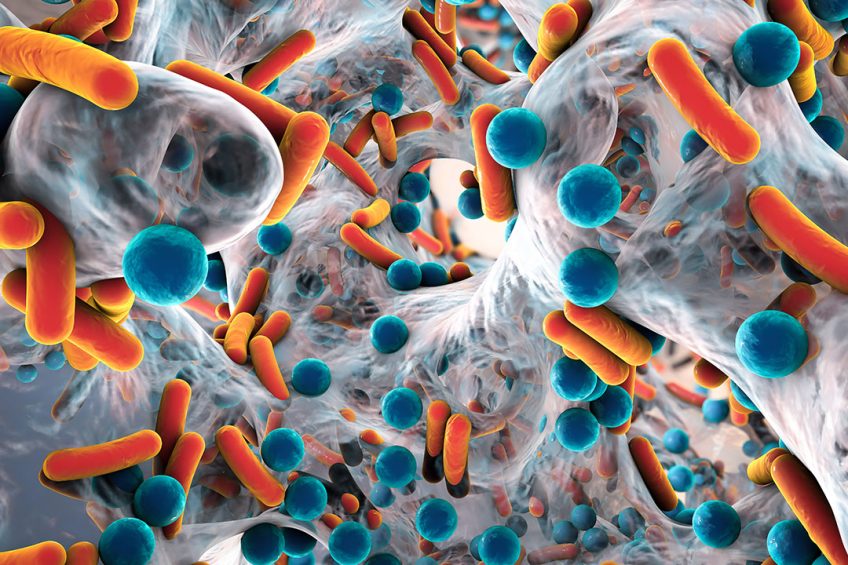

Microbes are everywhere. In farm buildings, all surfaces – floors, walls, ceilings and equipment – are colonised by micro-organisms, mainly in the form of biofilms (see box). They can be harmless, positive or negative for the animals if they contain pathogens.

Before a new batch of animals enters the building, cleaning and disinfection are necessary. However, surfaces do not remain sterile. Micro-organisms carried over from the animal environment and from the new animals themselves quickly start recolonising the surfaces, forming biofilms. These micro-organisms can be undesired bacteria or potential pathogens.

What are biofilms?

A biofilm is a community of micro-organisms fixed to a surface. They secrete a protective extracellular matrix, which can represent 85% of the biofilm biomass. A biofilm can be formed either by beneficial (i.e. positive biofilms) or by undesirable (i.e. negative biofilms) bacteria. A major concern is that some pathogenic bacteria in a biofilm form can be 10 to 1,000 times more resistant to antimicrobials or disinfectants compared to isolated bacteria.

A positive bacteria biofilm

What if beneficial bacteria were applied to building surfaces and equipment right after cleaning and disinfection? If they could grow into a positive bacteria biofilm inside the building, that would leave less room for negative biofilms to develop. This is the basis of the “positive biofilm” concept, a new approach to biosecurity management. It has 3 main steps:

1. Cleaning;

2. Disinfection; and

3. Application of selected bacteria that will form a positive biofilm.

Farm trials and in vitro studies have shown the potential of this new concept as part of the hygiene management toolbox. To develop a positive biofilm solution, Lallemand Animal Nutrition selected bacteria strains for their ability to form a biofilm and rapidly occupy the environment. The positive biofilm formed by the selected bacteria rapidly takes up the empty space on farm surfaces: in vitro testing showed 90% of surface coverage within 12 hours, leaving less room for undesired bacteria. The selected bacteria were formulated into a specific adhesive blend that can be sprayed on both vertical and horizontal surfaces.

An external in vitro study was conducted by the INRA Micalis Institute in Paris, France. It allowed scientists to visualise the interaction between the positive biofilm and different microorganisms (Staphylococcus aureus HG003, Listeria monocytogenes LO28, Escherichia coli SS2 and E. coli 977 in this case).

Plates were inoculated either with the positive biofilm formula or the tested micro-organism alone (control). After 24 hours, the tested micro-organisms were added on top of the positive biofilm. Figure 1 shows one example of the positive and negative biofilms visualisation.

To quantify those results, the researchers analysed the microscopic images to calculate relative biofilm volumes (Figure 2). For the four micro-organisms tested, pre-treatment with positive biofilm helped to avoid colonisation by undesirable micro-organisms.

In pig farming, a high level of hygiene and biosecurity can significantly improve production costs. The difference in profitability between swine farms with high biosecurity levels and those with lower levels has been estimated at around € 200/sow/year. In that context, the positive biofilm approach is of particular interest in maternity and post-weaning phases. Several on-farm trials indicate benefits in both environments.

Preserving piglets’ environment

A five-month trial was carried out with 3 consecutive piglet batches, for a total of 2,318 piglets, on a commercial farm. The positive biofilm was applied in two rooms. There were also two control rooms. Microbial sampling was performed during the first batch within the animals’ surroundings (specific petri dishes left on slates). The positive biofilm generated a positive microbial environment. Consequently, the development of undesirable bacteria in the animal environment (Streptococci, coliforms) was lower. As a consequence, the overall piglet mortality rate (in the three batches) was reduced from 1.46% (control rooms) to 0.43% (biofilm rooms).

It was concluded from the trial that applying a positive biofilm solution to complement cleaning and disinfection procedures helps maintain a safe microbial environment before the entry of the animals and, thus, contributes to preserving the good hygiene conditions of the building.

Controlling the farrowing room microbiota

In farrowing rooms, a trial conducted at a commercial farm in Italy showed similar benefits. The positive biofilm was applied on walls and floors of the farrowing room four hours after disinfection and three days prior to the sows’ entry.

Microbial sampling in the environment was carried out on slatted floors at different times. Again, the positive biofilm solution helped to maintain a positive microbial balance in the building. The development of undesired micro-organisms was lower than in the control room:

- Staphylococcus species were present in both treated and control rooms and on both plastic walls and slatted floors. In the control room, bacteria counts showed an increase over time of Staphylococcus species; in the room treated with a positive biofilm, the speed of growth was almost stabilised from 2.9 to 3.0 log/cm2. At day 4, the Staphylococcus species population was lower in the treated room (Figure 3).

- Streptococcus species were only observed on slatted floor surfaces. Again, the positive biofilm implementation helped keep good hygiene conditions.

References available on request.