Plenty of pig innovations at SPACE 2018

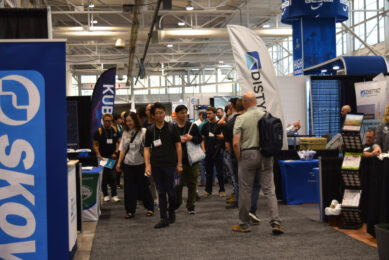

A wide range of pig innovations could be viewed this year at the annual animal husbandry show SPACE, held September 11-14 in Rennes, France.

The event was being held for the 32nd time, with 1,410 exhibitors from 42 countries worldwide. Visitor numbers came down to 108,347 from 121 countries, which represented a slight downturn in comparison to the 2017 edition of the show.

Main theme this year at SPACE was similar to that of 2017: robotics. Various pieces of equipment were demonstrated which make the job easier for the farmer.

Fournier: pig-friendly floor

Fournier’s Well’Floor concept is aimed at making a pen floor more pig friendly. It is a stainless steel tray containing rooting material and which has the same dimensions as a conventional concrete slatted panel. Hence it can be substituted for a concrete slatted section as and where necessary. A number of these trays can be fitted in random locations if the pen is very large, whereas in a small pen one tray would be sufficient.

This innovation received a 3-star award.

Weda: feeding valve with transparent cover

Equipment for liquid feed is often sophisticated and things may block up. In a wet feed system, valves are often a pinch point. Hence liquid feeding specialist Weda came up with its PV4 Feeding Valve, which has a transparent cover that makes checking the valve very easy. A red LED light also indicates a whether the valve is working properly or not.

This innovation received a 3-star award.

Neotec-Vision: Correct stunning checker

Neotec-Vision were exhibiting their Stunning Checker. This is an automatic image analysis system designed to assess the correct stunning of pigs pre-slaughter. The system assesses the corneal reflex of the pig and uses real-time image analysis to alert the operator when blinking is detected.

This innovation received a 2-star award.

At SPACE 2017, Pig Progress interviewed Asserva’s CEO Dominique Cantin. How does he feel about precision farming?

Asserva: Trolley to reduce bending

Technology company Asserva teamed up with the French Pork and Pig Institute (IFIP). The institute came up with the idea of a trolley which would reduce bending. It was commercially developed by Asserva. The net result is the Smart’Care trolley, a box on wheels which can be raised or lowered by a winch. In the lowered position, piglets are moved from the farrowing pen into the box. The box is then winched up to waist level after which piglets can be processed with a minimum of bending. If piglets have an electronic tag, weights are recorded automatically. After treatment the piglets pass through a small hatch and slide down a ramp, back to the sow. The equipment is made of stainless steel which makes cleaning and disinfection easy to carry out.

This innovation received a 1-star award.

Fancom: Recording pig weight

Assessing finisher weight by eye demands a great deal of skill whereas weighing finishing pigs individually is accurate but time consuming. Fancom were exhibiting their Eyegrow automatic weight monitor for finisher pigs, which uses a moveable 3D overhead camera. Eyegrow is 97% accurate and records pig weights along with daily liveweight gain.

This innovation received a 1-star award.

Skot: Heat source

A heat source is required at farrowing to stop overlaying and warm up newly born piglets. Some producers swear by heat mats but many others still prefer lamps as a lamp emits light as well as heat. Skot introduced ‘Sunskot’, a new generation heat lamp which incorporates a thin conductive layer of a special alloy on a square glass panel.

This innovation received a 1-star award.

Can’t get enough of innovations? Here are the pig prize winners at the upcoming EuroTier

Denkavit: star-shaped soft pellet

Denkavit feel that their Mellow Go star-shaped soft pellet will be irresistible to young piglets, due to its texture and palatability. It is being fed from 3 days to 19 days post-farrowing and sold only in 15 kg packs which ensures Mellow Go keeps fresh.

This innovation received a 1-star award.

Vitalac: colostrum assessment tool

With highly prolific sows, quality colostrum is vital for a good start in life. Belgium-based Vitalac has created the tool Scop’Ig for assessing the immune quality of colostrum. The tool makes it possible to interpret the Ig content of colostrum as well as to evaluate its variability. Then through feeding it is possible to improve the amount of colostrum the sow produces. According to Vitalac, the tool could be included in breeding company selection indices.

This innovation received a 1-star award.

Asserva: Automatic injection device

Asserva was also demonstrating its automatic injection device. This is a wheel-mounted steel frame to which are attached 2 angled parallel conveyors, in a V-shaped configuration. Piglets are funnelled at ground level towards the conveyors which gently grip the piglets and at the same time a gun automatically injects them.

The next edition of SPACE will take place from 10 through 13 September, 2019.