Farm visit: Viva Las Vegas in the pig barn

What happens in Vegas, stays in Vegas, they say. Yet, that does not apply to waste from the thousands of hotel and casino visitors. What happens to that? The pigs at Las Vegas Livestock, located in Nevada, USA, have a fair idea how to safely turn waste into animal protein.

The Combs family has produced slaughter pigs for more than 50 years. The used excess food and food waste from hotels and casinos in the million dollar city of Las Vegas to feed them. It started when Robert Combs. He got the idea to feed pigs with the food waste from the big city’s hotels in 1963. This was an innovation back then, that had not been seen before in the state.

Sustainability principle

The idea took off and Robert Combs’ 2 sons Clint Combs, now 53, and James Hank Combs, now 57, joined the family business after obtaining their university degrees. Father and sons wanted to recycle all waste from the large hotels and casinos. Not only food waste, but all other waste from daily operations as well.

Their vision was to keep food waste away from traditional landfills for health reasons. The trio also wanted to make people understand the sustainability principle of recycling all waste. It took several years to realise this vision. Meanwhile, they continued to produce pigs with feed from the food waste in Las Vegas. Slowly, the hotel industry started to understand their idea of recycling all waste.

Start of Las Vegas Livestock

The 2 brothers established their recycling company Combs Brothers LLV in 2004. In 2017, the father’s pig production farm, known as RC Farms, had become too small and they had to move it to a new location adjacent to several landfill sorting sites in an area near Interstate 15, about 50 km northeast of Las Vegas. That was the start of the subsidiary called Las Vegas Livestock (LVL).

The pig farm in Las Vegas

The brothers brought in their niece, Sarah Stellard, to the new pig farm as an operations manager. She is a 7th-generation farmer and graduated from Colorado State University with a master’s degree in animal science. She moved to Las Vegas in 2016 to help start the new farm.

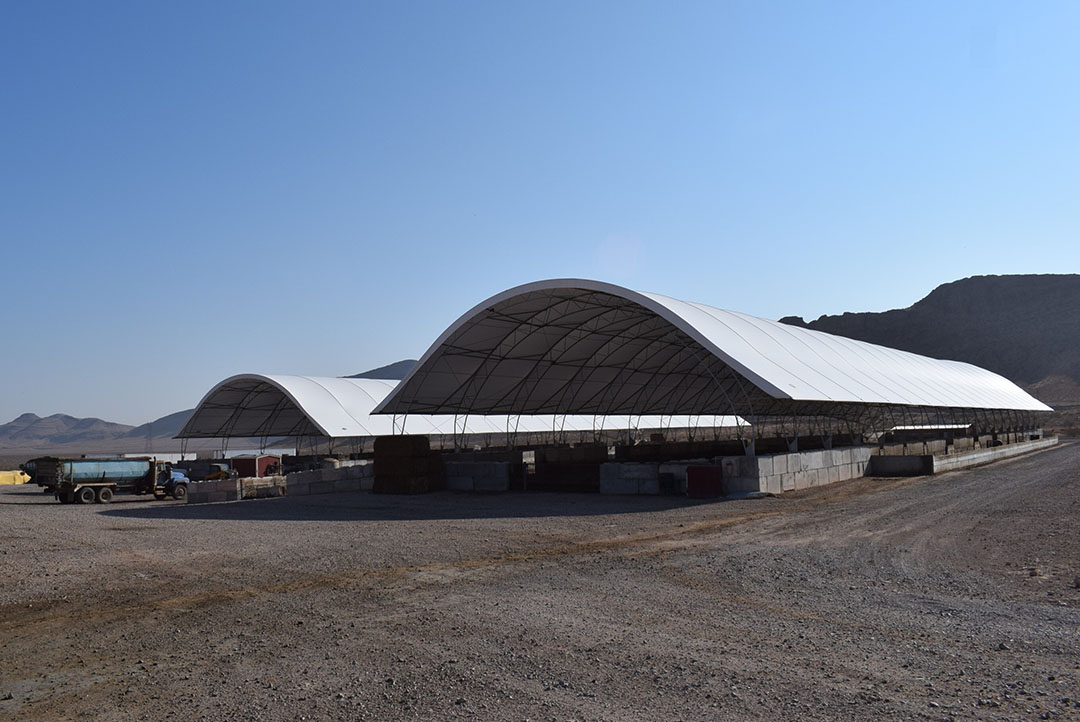

The large pig barns are situated in the valley, 1 km from the highway. Each barn, which is the size of a football field, is covered with steel sheets and surrounded by a wall of almost 1 m, and with a feed aisle where the pigs are fed 6 times a day. There is room for 500 to 600 pigs in each of the 7 barns.

Stellard says, “We buy the piglets from piglet producers in Iowa and Nebraska – an 8 to 10 hour drive – at a weight of about 20 kg. They stay here for about 6 months to reach a weight of about 120 kg. We then deliver the pigs to a slaughterhouse in Los Angeles. The transport time is approximately 6 hours. We buy wood chips from palm trees and straw for bedding in the large free-standing barns, and the mucking is done after each team is sent to the slaughterhouse. Slurry and dung from the pigs mix with the wood chips and we have no work with daily mulching from the large barn.

After half a year, the layer of chips, straw and dung from the pigs is approximately 50 cm high, and we remove it before putting in a new group. We compost this manure, and after a year we sell it to other farmers who use it as fertiliser in their plant production. This way, we can say that our production is completely CO2 neutral and very climate friendly.”

The feed plant

Stellard continues to explain, “We have a vet who is permanently attached to the herd.He comes to visit once every quarter, but can be called in if necessary. Because of the warm and dry climate, we usually have no disease problems. However, outbreaks of pneumonia can occur, but we treat this with antibiotics.”

The farm has a feed processing plant, constructed by father Combs and one of the Combs brothers. They are constantly improving it. When the food waste arrives by truck from Las Vegas, it is either in containers or in cardboard packaging. Before it is filled into a hopper, the packaging is removed, after which, a conveyor belt takes the food scraps to a press, where all organic material is pressed out of the packaging. Then, the food scraps are passed on to a large boiler.

During the process, any plastic residue and metal are sucked away by a magnet. In the large kettle, the leftover food is mixed with water and boiled for half an hour at a temperature of 230°C. The liquid “feed” is then taken to a storage silo. From here it is tapped by a tank truck, which fills it 6 times a day into the long feed troughs in the individual stables.

Inactivating ASF

Stellard says, “While we always do our utmost to keep animal diseases from entering our operation, we have learned that cooking the food for 30 mins to boiling, as is required for our operation per the swine health protection act, inactivates ASF from any contaminated meats that may enter our system. Cooking the feed is an important line of defense against bacteria and viruses alike. We work closely with our state and local vets to monitor herd health and report any concerns.”

“Before we give the liquid feed to the pigs, we analyse it so we can stop possible infections. Up until now, in the 4 years we have been producing feed here on-site, we have not had any problems. However, we struggle a bit with the fact that the salt content is a little too high sometimes, but not so high that we cannot use it for the pigs. In addition to being fed 6 times a day, the pigs have water available in the barn around the clock.”

The goal is 20,000 pigs

Just like many other industries, the Combs farm went through rough times when Covid-19 struck. Stellard explains, “After Covid-19 shut down the entire tourist industry in Las Vegas for over a year, we have not been able to produce as many pigs.”

In spring 2023 the farm was stocked with 5,000 pigs. She adds, “In the short term, the goal is to produce 20,000 pigs annually. In the Los Angeles area, there is a great demand for pork, which is produced from leftover food.”