Macroalgal extracts to counteract heat stress in dairy

The consequences of heat stress in the dairy industry are the most economically severe, the reduction in revenue associated with heat stress stems from decreased feed intake, altered metabolism, reduced milk yield, impaired reproductive performance, and increased health-related costs.

Heat stress is a global concern and if climate change predictions continue, livestock health and productivity will continue to be affected. The annual global losses associated to poor performance during periods of heat stress in the livestock industry are approximately > USD$500 billion/year. During heat stress, cows try to dissipate heat via several thermoregulatory mechanisms, among others by behavioural changes such as reducing feed intake that can reduce milk yield up to 50%. Besides, physiological thermoregulatory mechanisms such as diverting blood flow to skin and extremities results in a lower delivery of oxygen to the enterocytes (hypoxia), an increase of reactive oxygen species production (ROS) and ultimately damage to the tight junction complexes in the intestinal villi that negatively impact nutrient uptake and aggravate low productivity. Moreover, the loss of gut barrier function leads to a higher translocation of pathogens and a proinflammatory response that will consume glucose, contributing to the reduction in the milk yield since lactose is the main osmoregulatory factor of milk yield. It is paramount to find nutritional strategies to alleviate the damage created by heat stress. Macroalgal extracts can be integral part of heat stress management programmes due to their positive effects on gut barrier function and modulation of the immune response.

Unique structural features

Parietal polysaccharides of seaweeds present structural complexity and a unique composition that confer them high reactivity and explain their biological properties when used in animals. The complexity and biological reactivity of seaweed polysaccharides stem from the nature of the sugar units, which are diverse and sometimes rare, such as uronic acids, xylose and rhamnose; the variety of glycosidic bonds leading to their branched structure and the presence of sulphate groups. Furthermore, their polyanionic structure and solubility increase their reactivity and enable their recognition by host cells. Sulphated polysaccharides are characteristic of macroalgae (they are not found in terrestrial plants, nor freshwater microalgae nor yeast cell walls). Olmix Group marine bioactive ingredient extraction know-how has led to the development of an in-feed product, Algimun, which is based on the combination of 2 bioactive macroalgal extracts: MSP Barrier, a red algal extract, which enhances the gut barrier function; and MSP Immunity, a green algal extract, that modulates innate and adaptive immune responses. Algimun bioactive molecules proved to be resistant to feed processing, especially to heat treatment and extrusion.

Gut barrier promoting properties

The effects of MSP Barrier on intestinal barrier function were demonstrated in an in vivo scientific study. MSP Barrier reduced the paracellular passage of FITC-dextran (gut permeability biomarker) to the blood stream in an animal model known to trigger inflammation in the gut mucosa and consequently a loss of its integrity. Other studies have proven, in vitro, that MSP Barrier upregulates the expression of genes encoding proteins which are required for an optimal functioning of the tight junction complexes; and the expression of genes encoding for major mucus proteins which prevents pathogen attachment and colonization of the gut epithelium. MSP Barrier strengthens intestinal mucosa in the presence of a pathogenic strain of Escherichia coli as observed by an increase of transepithelial electrical resistance (TEER) when compared to the positive control group. Further research has shown that MSP Immunity has the capacity to modulate the synthesis of immune mediators involved in defence mechanisms within the innate and the adaptive immune response, among others, the recruitment and activation of antigen-presenting cells, the differentiation and proliferation of different immune cell populations, while inducing immune tolerance thanks to its anti-inflammatory properties. MSP Immunity also upregulates the expression of immune mediators with anti-inflammatory activities.

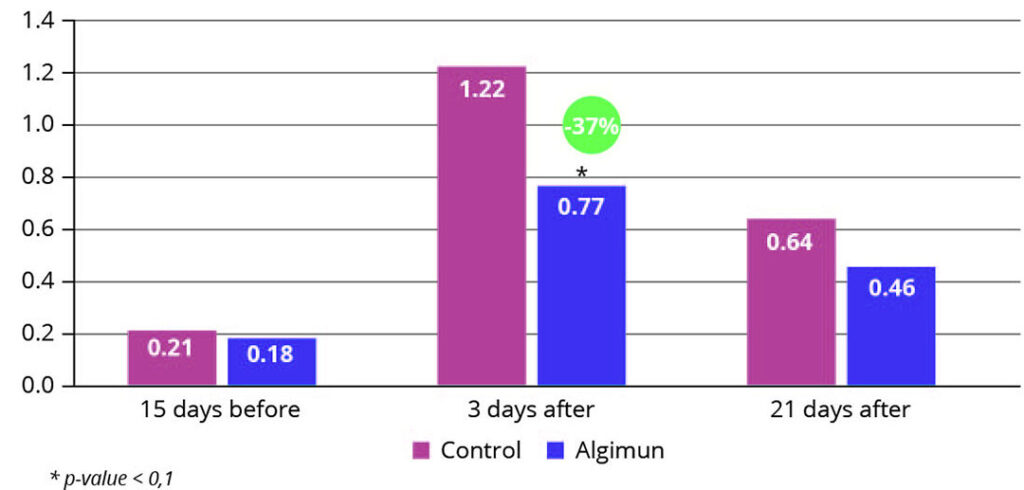

Figure 1 – Haptoglobin serum levels (mg/mL) in the peripartum (days from calving).

Effect of Algimun on cow health and performance

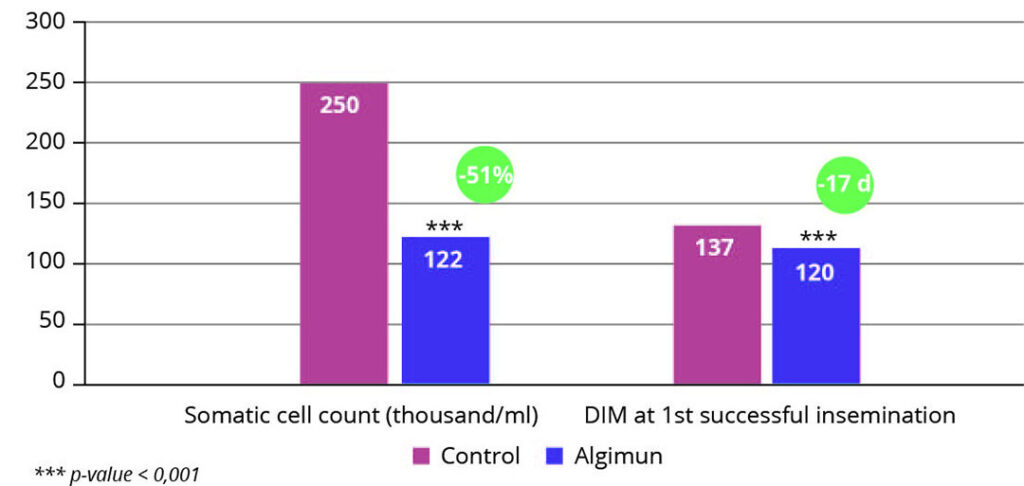

Algimun has demonstrated to improve health and productivity as well as reduced reproduction delays associated with heat stress. The use of Algimun in Spanish farms experiencing heat stress (average 33°C during the trial) during the dry period (60 d before calving) resulted in significant improvement of health and production parameters: reduction of haptoglobin levels at day 3 post-calving (accounting for lower inflammatory status) (Figure 1), increase of milk yield (+2%, 0,84kg/cow/day at 90 days in milk p<0,001), reduction of somatic cells counts and of days in milk at first successful artificial insemination when compared to control group (-17d, p<0,001) (Figure 2). Algimun use led to a € 52 extra income per cow. Fresh cows during heat stress periods can benefit from using the product as observed in a 500 dairy commercial farm in Wisconsin (USA) in which supplemented fresh cows maintained their feed intake and rumination time. An improvement of colostrum quality (brix values >28 in Algimun group compared to brix values of 22 in control group), and a reduction of pathologies in the post-calving period (-19.4% of placenta retention occurrence and -47.2% of mastitis occurrence <60 DIM vs control group) were observed when given in the dry period feed in Italian farms. The macroalgae based solution, can be used as a natural alternative in-feed strategy to support dairy herds coping with heat stress by reinforcing gut barrier function and modulating immune response to maintain or improve productivity.

Figure 2 – Somatic cell count (*1000/mL) at 90 days in milk and average days in milk at 1st successful artificial insemination.

References available on request. The For Feed Team can be reached at animalcare.pm@olmix.com.