Winning one piglet per sow pre-weaning

Since the home farm of Detert Zuchttiere switched to Danish ?genetics, extra attention was needed to keep the large amount of young piglets alive. Owner Carl-Josef Detert found a solution by installing balance floors in his farrowing area.

Carl-Josef Detert, 49, is the successful owner of Detert Zuchttiere, which operates three multiplication farms in Germany. He breeds gilts for commercial production, since 2009 he has been doing this using DanAvl genetics.

The highly prolific and high health gilts, originating from Denmark are rapidly gaining in popularity all over Europe. Detert gets his roughly 25,000 breeding gilts per year sent throughout the country, as well as to neighbouring Poland, Belgium and the Netherlands.

Detert’s homebase has been Gronau, in the German state North Rhine Westphalia; he has been in charge of the century-old family property since 1992. Unlike most of the rest of his business, the home farm has been kept in use for regular pork production with a farrow-to-wean function. The farm has 650 sows; weaners of 28 kg are being transported to external farms for finishing.

Carl-Josef Detert, owner, Detert Farm: “With the balance floors, you can easily continue feeding or continue doing your work, it’s no longer needed to be around at farrowing.”

“The biggest advantage of producing piglets ourselves is that we can see how our sows function,” Detert explains about the sows he produces, describing them as ‘calm’ and ‘caring’. “It offers us the opportunity to experiment a little, as it is really important that we do not lose touch with business. It’s good to understand how these very, very fertile sows perform in practice.”

Highly prolific

The higher number of piglets per litter – in Detert’s case 15-20 piglets – also present a new problem in itself. The higher the numbers of piglets born, the higher the number of piglets that is likely to die before weaning.

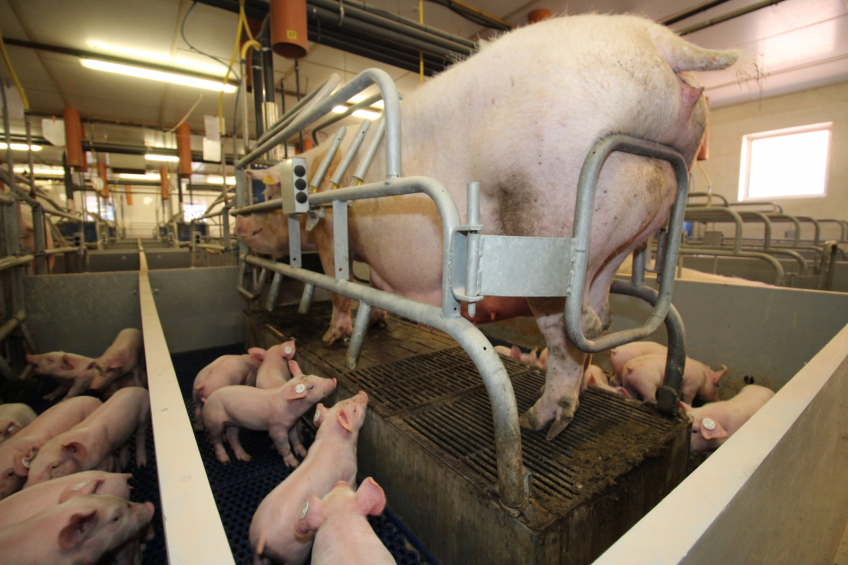

Colleague and in charge of piglet production, Dutchman Jos Nieuwenhuis, advised Detert to think about going for what they’d call in German a Hub-Senk-Boden, also known as a balance floor. This is a flooring system, developed about 15 years ago by Dutch flooring company Nooyen, for use inside farrowing crates – and widely applied in the Netherlands, Belgium and France, and also gaining momentum in Eastern Europe. What is key is the floor underneath the sow being flexible, when the sow rises to eat, she touches a sensor pneumatically pushing up her floor. This way, piglets will be temporarily separated from their mothers by a level difference of about 25-30 cm, thus reducing the number of crushed piglets.

Initially Detert had second thoughts about this system, the main being that advanced technology and the robust reality of a pig house may not go well together. He also intended to work with low costs of production. Now, three years after the installation of a first set of 46 floors in a newly added sow barn, figures have proved in favour of the new floors, as pre-weaning mortality went down by 0.4-0.5 piglets per litter, translating into almost one piglet extra per sow per year. His son, a mathematician, had deciphered that with this speed, return-on-investment would follow after 2.5 years. No wonder that soon after the initial 46 crates, another 30 existing crate capacity was retrofitted with the system. In total, seven of 12 farrowing departments now have balance floors.

For the piglets who remain ‘downstairs’, it is just a matter of time before their mother will be at their level again.

More strategies for newborn piglets

One other strategy the farm applies to get all newborn piglets through the early stages of life is by providing additional sources of milk. For this, special pink cups are provided, which are connected through pipes to a central kitchen. The system and the milk are provided by the German animal nutrition company Bröring.

Disease risk is also reduced as much as possible, as DanAvl genetics usually are sold as Specific Pathogen Free (SPF), which means that the breeding material is guaranteed free from certain pathogens. Knowing that various pig farms are in the direct surroundings, for security reasons Detert does vaccinate both sows and piglets against PCV2 – especially in the sows Detert notices a positive tranquility effect. In addition, the piglets are vaccinated against PRRS and mycoplasma.

Farm buildings with free access stalls

The Detert farm consists in total of four buildings, each having different functions. Apart from the farrowing rooms, one house is used for gestating sows. To comply with EU legislation, the sows are kept in group housing; Detert chose for free access stalls. As can be seen more often, usually the sows prefer the comfort of their own stall rather than take a stroll in the common zone.

The sows are confined in the first four weeks of gestation. Some insemination rooms feature Nooyen floors, which offer the possibility to open a small gutter right behind the sows. This way, manure can fall right into the basement, and cleaning is relatively easy, leading to a relatively clean floor when compared to concrete floors.

Some insemination rooms feature a small gutter right behind the sows. This way, manure can fall right into the basement.

Due to an abundance of feed mills in the direct surroundings, a commercially produced diet is available for the sows. The only elements added to the feed on-farm is corn-cob-mix (CCM).

Two weaner buildings complete the complex. The piglets are being weaned at the age of 26 days and stay on the farm until they are about 28-30 kg. Then they are shipped to finishing farms within a 20 km radius. One of these is owned by Detert himself, the others are contract finishers.

At Detert farm, the piglets are being weaned at the age of 26 days and stay on the farm until they are about 28-30 kg.

Biogas and solar panels on the pig farm

For a long time Germany has had a national focus on encouraging to develop more green energy sources – the ongoing emphasis on bioenergy at EuroTier confirms this. Since 2000, Germany has had the Renewable Energy Act (EEG), subsidising the investment in all kinds of sources of renewable energy. Many pig farmers made use of this regulation and the Detert facility has been no exception.

Since 2001, the farm has had a biogas facility. The current 705 kW biogas plant was built in 2006 and consists of four large silos where several ingredients are put together to ferment in stages. Apart from the pig’s manure, cattle manure is trucked in from a nearby farm, but also silage maize is being used. These are predominantly grown on the farm’s grounds. Gas that is produced will be converted into electricity energy on-farm, after which it is used to keep the farm running. A small part is being shared with the Gronau city electricity network.

In addition, solar panels are covering the roofs of most farm buildings. This energy is virtually all used on-farm.

Assessing the balance floor system

Coming back to the balance floors, which were made to fit Detert’s pen size of 190 x 260 mm – how about Detert’s initial second thoughts? He says that he’s had to change or repair a few minor things here and there and once the pneumatic pump had to be replaced, but on the whole the number of repairs have been very manageable.

Nieuwenhuis points out that zero pre-weaning mortality is not possible either. The number of categories has simply been reduced. Main categories now are ‘stillborn’ as well as ‘Kümmer’, which means as much as ‘too light to stand a chance’.

From outside the compartment, all floors can be manually controlled – e.g. for vaccination purposes.

Detert is happy to point to several other advantages the system has given him, one being that catching the piglets for treatment does not take as much time as the sows can be fixated on a higher level with one push of a button, leaving the pigs fewer options to run away. Another is a gain of labour time, as the team on the farm always had felt forced to keep a close eye on the newborn litters to avoid crushing. Detert says, “And now, with the balance floors, you can easily continue feeding or continue doing your work, it’s no longer needed to be around.”

So an interesting discussion evolved as to whether the balance floor system has saved the weakest piglets or the most active ones. There is something to say for both. On one hand, theoretically one would think it is the weakest ones, as they may be the last to notice that their mother is about to lie down again. On the other, Detert and Nieuwenhuis say practical experience shows it was usually the most active ones. They usually restlessly run around and thus happen to be ‘in the wrong place at the wrong time’.

Detert farm, Gronau-Epe, Germany

The Detert facility in Gronau-Epe, Germany is a 650 sow farrow-to-weaning facility. The farm has a 3,600 weaner capacity. Sows on average reach 2.32 litters per year. Liveborn pigs per sow per year are at 16.5, and the farm reaches 14.8 pigs weaned per sow per litter, resulting in a 34.3 piglets weaned per sow per year. The farm also uses 190 ha, 40 ha of which is owned.

This article appeared Pig Progress magazine, volume 31, no. 6