What the textbooks don’t tell you about… Curtain-blind operation

Curtains or blinds have grown in popularity in the more temperate / warmer parts of the world because they are simple and cheap to install, but they tend to be poorly designed and badly operated on too many pig farms. A few notes from my own experiences may be of help?

By John Gadd

Curtains on 90% of the farms are designed for a daytime temperature band of 26°C to 34°C, where a reasonable if gentle flow of air is required across the pigs, along with spray cooling. Under these conditions they work well. However, thought is rarely given to late evening and night-time temperatures which can often fall to cause chilling, even in warm climates. This is especially dangerous for young pigs in the 20-40 kg stage. Chilling causes stress and stress lowers the animal’s immune defences to many diseases, especially respiratory ones.

Curtain alteration is too infrequent

As the warm evening turns into a cooler, chilly or even cold night, the curtain is the main device to retain the correct air temperature just above the pigs’ LCT (Lower Critical Temperature). Being manually operated, the curtains are usually raised (to conserve heat) too late; as a result the pigs are chilled and stressed as the outside temperature falls. I have measured evening temperature changes in the tropics from 7-12 pm. In each case I asked the owner what he thought the range over this period was, the reply being 4-5°C. The instruments indicated it was actually 8°-12°C. A single curtain adjustment meant that all pigs were outside the correct range for 4 hours, and from midnight onwards temperatures were frequently 2°C below LCT for older pigs and as much as 5°C below LCT for weaners.

Solving the problem

• Automate the curtain

No stockman, however diligent, can keep pace with the diurnal temperature changes twice a day (morning and evening), and maybe further changes during the day or night if the weather alters. An automatic controller makes over 30 adjustments in a normal day, and sometimes more. A sample series of temperature sensors (normally three for a building 10 metres wide x 30-40 metres long) linked to a controller which instructs a curtain motor, (or motors, see later) will keep the temperature bands close to the pigs’ LCT (this can be preset into the controller according to the age of the pig, type of floor surface, degree of roof insulation and feed density etc) so that the pig is not chilled even if the outside temperature falls either quickly or slowly.

• Make the curtains fit snugly

The top should be rigid and fit into a slot. The sides should ‘fold’ into a box, or if on rollers should rise and fall via a narrow slot. Both are to reduce draughts, and this is especially important for weaners up to about 20 kg. In non-tropical areas solid louvers are better than curtains, but are around three times more expensive to construct.

• Quartile the building

‘Quartiling’ is to divide the building into four squares or broad rectangles served by at least two curtains down the side of the building, not just one (Figure 1). Just having one blind down one side is too inflexible as it cannot cope with the sun’s daytime movement from horizon to horizon or sufficiently cope with changes in wind direction. Plus curtains are often too long, so the upper gap tends, especially after time, to be unequal along its length. This is not so important during the day, but can be critical at dusk and during the night. Maximum operational length at the time of writing is about 30-35 metres. If the building is longer, use several blinds.

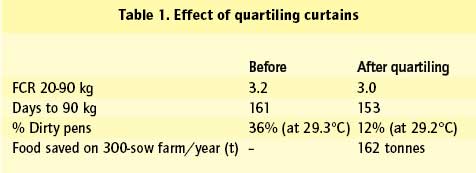

What happened when a piggery was quartiled?

Table 1 shows a massive saving of162 tons of feed/year. The only difference was that two buildings (nursery and finishing) were converted from manually operated curtains, to quartiled automatically- controlled curtains. The cost of conversion was 80% of the cost of the food saved, thus the payback was in 10 months. Not surprisingly the farm is now fully converted to automatic curtaining.