Weighing at weaning can help identify diseases early

French researchers are currently testing a tool capable of alerting swine farmers when weaner pigs show signs that might indicate the presence of pathogens.

The tool is being developed at the pig station of the French Pork and Pig Institute (IFIP) in Romillé, France. IFIP researcher Michel Marcon wrote about it in the September-October issue of TechPorc, the magazine co-published by IFIP and the Chamber of Agriculture of Bretagne.

The equipment allows figuring out the feeding and water behaviour of each piglet. Connected feeders and drinkers will send positive signals, allowing the development of an early pathology detection tool. The individual and daily weight of piglets forms the basis, as without these data, early detection of pathologies will be a longer challenge and may even become impossible to meet.

A connected weighing in post-weaning?

Until now, in order to obtain piglet weight in the station, an operator had to manually weigh them one by one every week, or even several times a week. Not only was this method time-consuming and intrusive, it also modified both water and food intake behaviour of animals. Nevertheless, a sudden change of piglet behaviour may be a signal of disease – hence there is a challenge for early detection.

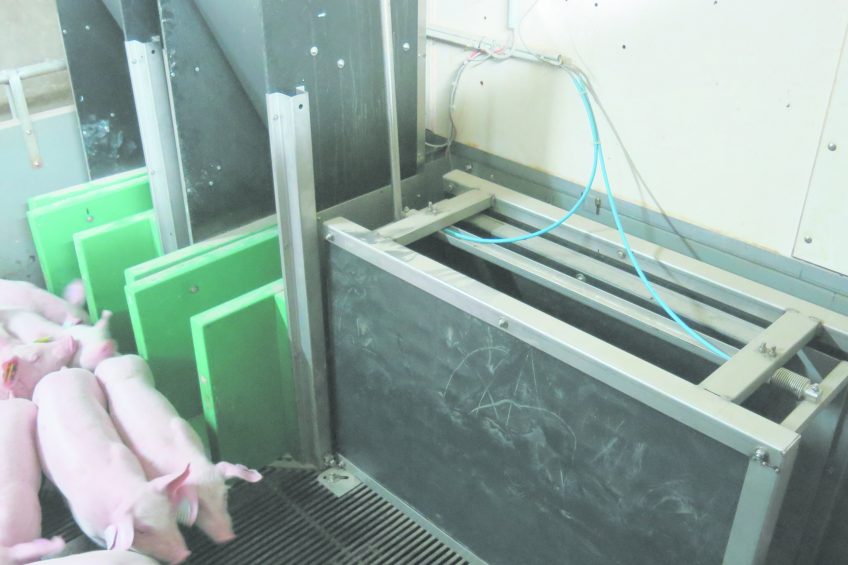

IFIP and Asserva therefore developed connected scales, to be placed in front of a trough, see Figure 1. The prototype is composed of a U-shaped device, made of stainless steel suspended on 2 strain gauges to allow precise weight measuring. Surrounding sides prevent other animals from disturbing the measurement.

Figure 1 – 3D illustration of the device.

Source: IFIP

A connected Radio Frequency Identification (RFID) antenna is positioned behind the trough. The device weighs both the trough as well as the animal, allowing an exact weight measure, even when the animal is drinking. Each animal must be equipped with an RFID chip, which can be detected by the antenna. Information related to its watering behaviour is transmitted, recorded and analysed on a computer.

Why individual weight monitoring over time?

Individual weights are recorded in real time. A ‘cleansing’ algorithm of the weights measured allows strongly deviating values to be excluded or corrected, e.g. when 2 piglets would be present inside the station simultaneously or when an animal would be detected while only its 2 front legs are on the weighing machine.

As a result, measured weights are very precise, and since the animal is weighed at various moments during the day, it hardly ever occurs that no data are being obtained.

Prospects

The results obtained using the prototype are very promising. The experimental station is therefore equipping 12 post-weaning boxes with this device. Thus, routine weight measurement, associated with connected feeders and drinkers, in addition to the possibility of calculating individual consumption indices, makes it possible to consider the early detection of pathologies. Indeed, a very strong link between levels of water consumption and the weight of animals brings a fine and routine knowledge of their weight, which will help building a tool capable of alerting the breeder when a piglet shows signs indicating the potential appearance of a pathology.

Mr Marcon said, “There are, however, still some obstacles to overcome in order to imagine meeting this technology in pig farms.” He was thinking of:

- The prototype price is still too high to imagine equipping all the boxes of a pig unit;

- The profitability of these devices is based on the ability to make the early detection of pathologies in a performing way, but the tools of this type are not finalised yet;

- This technology requires the use of RFID chips on all the piglets and the price of these chips is still too high.