Bringing together housing, stockmanship and breeding

Loose housed sows during farrowing and lactation, this is the goal of Australian pig producer, Laurie Brosnan. This brings extra management challenges including keeping piglet mortality down.

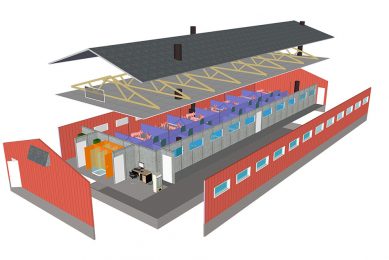

Australia may not have the largest pig production in the world, but that doesn’t mean they are not taking a lead and paving the way for future pig production. In 2014 Laurie Brosnan, Bettapork, established a new 1,400 sow herd with loose lactating sows in environmentally controlled buildings.

Being located in Queensland with tropical climate conditions means that temperatures come up to around 45°C in the summer and so the outside conditions are challenging. Building facilities for future pig production that ensures a high level of efficiency and productivity and at the same time encompasses high animal welfare only adds to the challenges.

The farrowing shed next door to the gestating sows is comprised of ten rooms, with 36 pens each. During farrowing and lactation sows are housed in SWAP farrowing pens from Jyden. The pens are fully slatted with hot water heat pads in the covered creep area for the piglets. Sow feeding is automatic and with a tablet in hand, the staff can easily control and adjust feed for each sow on a daily basis when they walk through the shed. Each sow is set on a specific feed curve, according to parity and condition, this then automatically increases the amount of feed through lactation. The sows at Bettapork are loose during farrowing and lactation because Brosnan believes that is the way to produce pigs in the future.

Stockmanship and piglet survival

Management requirements are higher when sows are loose housed but Brosnan is determined to make it work and at Bettapork there is a constant focus on learning from experience and to keep improving. Instead of seeing challenges and limitations when performance is not satisfactory, they focus on the possibilities and the ways forward.

Willpower and good intentions are not enough to make a

success. Actions must be taken and attention to detail can make the difference. Recently cameras were installed in the

farrowing shed. Recordings from these are used to keep an eye on the animals and to educate staff. The recordings provide Brosnan with information and allows for information based decisions rather than guessing. The purpose of the cameras is also to provide more knowledge to the outside world and to share experiences with scientists and industry people to create a win-win situation.

Focused on routines

It is no secret that one of the challenges with free farrowing is bringing down piglet mortality. At Bettapork pre-weaning losses are currently fluctuating around 14-20% where peaks are caused by outbreaks of diarrhoea, but the aim is to bring mortality down to 10%. A key feature of this SWAP farrowing system is the opportunity to use a simple form of confinement for a few days after farrowing where the piglets need protection. However, even though Brosnan has the option to confine the farrowing sows, he has decided to keep the sows loose at all times. Loose farrowing sows are challenging for people who have worked with pigs their whole lives. Yet, at Bettapork, this is even more the case, since a lot of staff are backpackers seeking work for a few months at a time without any previous experience with pigs or farming. Simple and strict routines, and proper training is even more important. Brosnan explains, “Strict procedures are in place from the simplest of tasks to the more complex tasks. Of course the more complex duties are performed by our skilled stockpersons. In addition, where possible, we have automated duties that would normally be performed by stockpersons.”

Brosnan uses backpackers because it is hard to find qualified employees – just like in a lot of other more remote places in Australia. An advantage of backpackers, though, is that it is easier to have nightshifts and constant surveillance of sows and piglets. At Bettapork, employees are present in the farrowing shed 24/7 throughout the week and they are carefully instructed on how they should handle the newborn piglets. The majority of piglet mortality occurs around farrowing and in the first days thereafter, so in order to keep mortality down, a lot of time and effort goes into this period. When asked what is the most important management tool, Brosnan says, “Supervision, supervision, supervision!! If a stockperson is around for the first two to four days after farrowing, then you can really reduce piglet losses.”

Every week approximately 65 sows give birth to an average of 12 live born piglets. Functional teats are counted and noted on the sow card so everyone knows how many piglets the sow can foster. At birth the piglets are dried with drying powder. This is important because it helps the piglets but also because it helps keep the pen dry in general. Split suckling is standard procedure to make sure that small piglets also get a space at the udder and some milk.

Turnover of staff and the workers’ limited experience with pig farming makes training and correct instruction key to achieving good results in the farrowing unit. Good stockmanship is often associated with lots of experience and a trained eye that sees things that others don’t. However, a systematic approach, proper training and follow-up is also an important part of good stockmanship – Bettapork is a very good example of this. Here, the guidelines are strict and the emphasis is on carrying out procedures systematically and correct. If mistakes are made, actions are taken to correct it and to make sure they don’t happen again. It is important to Brosnan that workers understand what their job is and how to do their best even though they are jumping in at the deep end. A lot of time and energy is therefore spent on instruction and training of staff but efforts are repaid in good production results and a modern, high performing site that keeps moving forward.

Breeding a sow to suit the environment

All the efforts that have been put into the free farrowing sows and the learning experiences that have come from it will benefit the new breeder site when they start up with free farrowing. In addition, research has documented a relationship between genetics and environment meaning that using the same system for breeder sows as well as production sows is beneficial. So today, Brosnan and his family are in the process of building a new farrowing shed for their nucleus site – also with loose housing.