Precision Livestock Farming – the way forward

In a world where farms become larger and larger, monitoring growth of individual animals may become an increasingly difficult task. Precision Livestock Farming helps to keep track of the animals’ performance – and make correct predictions as well.

There is no way professor Daniel Berckmans would be able to hide a bad day in the office when coming home. He says, “My wife can always tell when there is something wrong. I don’t know what it is that she sees, but she will see it straightaway. It just goes to show that creatures can give thousands of signals about what is going on inside – it just takes others to pick these up and interpret them in the right way.”

Now Prof Berckmans can consider himself a lucky man as at least one person will quickly find out what is going on inside his mind. But what if an animal in a house containing 1,000 others sends out signals of hunger, fear, hypothermia, pneumonia or stress? Who will pick these up? In a time when animal production facilities continue to grow, there does not seem to be a focus on keeping an eye on individual animals.

Or is there? Berckmans is heading the so-called ‘M3 Biores research laboratory’ at the Catholic University of Leuven, Belgium. The name of his research team, ‘M3 Biores’ refers to the measuring, modelling and management of bioresponses in humans and animals. This university has started focusing on these principles in 1992 and has expanded its knowledge into a vast range of application, not only in the livestock industry but also in for e.g. the world of football, aerospace, sleeping and cycling.

For the agricultural industry the application could be summarised as: permanently observing animals by the use of technical equipment, obtaining a wealth of information – and use this information for guiding farm management decisions. This strategy is often referred to as ‘Precision Livestock Farming’, or PLF.

Indicator

Having decided what exactly needs to be found out in an animal herd or flock, the biggest task is often to find the one or more simple indicator(s) which allow correct interpretations, Berckmans says. An indicator needs to be undisputable, and easy to observe by sensors, whether they are images or sounds. For instance, a good example to measure animal well-being in the poultry layer industry was found in the bioresponse of scratching. Prof Berckmans explains, “Ethologists have shown that chickens do not scratch when they feel threatened. So this means scratching in layers is one of the indicators of well-being, which is important to know in e.g. the use of aviary systems.” And, on the contrary – if this behaviour is not displayed, something may be wrong.

Over the years, the university has specialised in finding ways on how to detect and measure indicators like these – and have them interpreted by computer programmes. Camera use comes in handy in this respect, Berckmans says. A camera can observe animals from above – and any image of a layer from above will be reduced to an oval surface with a certain length and width, this is what is referred to as a 2D-approach. In case of a scratching action – the time factor is included and a dynamic model will appear from the 2D-approach. In this case, a layer’s surface, length and width will change. When this is done for many animals, a pattern of surfaces, lengths and widths will appear which allows a computer to deduce a flock’s behaviour.

Pigs

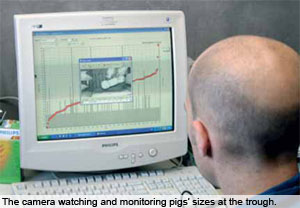

For pigs, the first result of this approach was launched at the last edition of VIV Europe, in Utrecht, the Netherlands. The university has had a long-standing collaboration with livestock management systems manufacturer Fancom, headquartered in Panningen, the Netherlands. It was this company that introduced a camera system for finishing pigs, called the ‘Eyescan’. Installed above a feed dispenser in pens for approximately 15 finishers, the camera can capture width and length of a pig, thus deducing its weight. Weight estimate accuracy can be guaranteed to approximately 97%, the company says. When this information is gathered from all pigs, a complete picture can be drawn up of the pen’s weight distribution. This, in turn, will greatly help enhance determining what kind of feed should be added for the rest of the finishing phase.

It is not the first time, camera use has been introduced in finishing houses, as some years ago, Pig Progress reported on a camera-equipped sorting sluice and the use of mobile cameras (see ‘An extra set of eyes for producers’, Pig Progress 22.08, 2006). This current approach however differs from the approaches mentioned a couple of years ago, in the sense that now smaller groups as used in north western Europe can be equipped with stationary equipment.

Additions

Since the approach of the new camera type has a firm basis in science, more applications are being prepared using bioresponses. Prof Erik Vranken, Catholic University Leuven, and connected to Fancom as research manager, explains more about these applications. “In poultry, the Eyenamic has been launched – a camera which indicates where activity is going on in the house. This gives information such as whether temperature is too hot or too cold. This principle could also be introduced in pigs.”

Trials with this type of camera monitoring system have already been carried out, focusing on activity and occupation density. Automatic aggression monitoring is a possible application. Prof Vranken says, “In addition, sound analysis can help reduce the use of antibiotics in pigs. Coughs will sound different when certain diseases come up and this can be registered through a microphone. In addition, water intake monitoring will also tell something about a herd’s health status. In case certain parameters change, an alarm can be given and a disease can be traced a long time before it becomes apparent (see Figure 1).”

The introduction of these kinds of systems will become inevitable in the future, Vranken says. “The society wants agriculture to keep a close eye on the animals all the time. When doing that with only human presence, it’s not a way we can go. The solution is to add more technology around the animals.”