Pleurisy: A stumbling block for pig producers

Groundbreaking research commissioned by BPEX has shown pleurisy is a massive stumbling block for both pig producers and processors.

It is costing as much as £2.26 a pig but producers could start reducing these losses now by signing up to the BPEX Pig Health Scheme (BPHS) and changing management systems to reduce stress on pigs.

Dr Dan Tucker, a senior lecturer in veterinary public health and pig medicine at the Cambridge Veterinary School who headed the investigations into pig pleurisy, said his team found 78% of all batches of UK pigs showed some indication of pleurisy, with 10% of those showing pleurisy running at more than 20%.

The researchers followed 80 batches of pigs through to slaughter, monitoring environment, performance and management techniques. They found the disease reduced growth rates and led to lower carcase weights, as well as increased ages at slaughter with additional feed costs.

The total economic impact was calculated at 226p/pig, not including veterinary costs, assuming a prevalence of 10%.

Further economic damage was also revealed during the processing stage, due to an increase in inspections, extra trimming, a reduction in line speed and associated staff costs.

Dr Tucker said: “People have known about pleurisy for a long time, but now we have firm statistical evidence showing the extent of this disease and revealing the considerable economic damage it causes.”

Studying historical data of 120 pig herds with a history of either a high prevalence of pleurisy (above 10% over the past two years), or a low incidence of pleurisy (less than 5% over the past two years), as well as problems caused by the disease at abattoirs, his team (which included representatives from the VLA and some major pig producers and processors) was able to identify a series of risk factors that led to a high incidence of the disease.

These included:

• Failure, or inability to implement strict all-in all-out management at unit, or building level

• Repeated mixing of pigs after weaning

• Repeated moving of pigs (even without mixing).

In addition, units with farrow-to-finish production systems had a higher incidence of pleurisy than ones with off-site rearing, where incidence was further reduced by operating wean-to-finish systems.

“We put these batches under the microscope and found significant differences between the two groups, which enabled us to identify some simple practices producers could follow to reduce the incidence of pleurisy.” said Dr Tucker.

These included:

• Cleaning and disinfecting finisher accommodation thoroughly between batches

• Extending the downtime for grower and finisher accommodation between batches to at least four days and ideally eight days

• Minimising the mixing and moving of pigs as much as possible, particularly during the growing period.

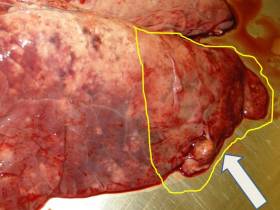

“This disease, which has few observable clinical symptoms and can only be diagnosed definitely in post-mortem inspections, is affecting most UK producers, but we now know that they can take action to reduce the impact of this disease,” said Dr Tucker.

©

“Personally, I think all producers should join the BPHS so that they and their vets get the data that will alert them to any pleurisy problems from the processors. The information is available. Producers just need to make sure they receive it. It could save them a lot of money.”

Congratulating BPEX on highlighting the pleurisy issue, one observer from the processing sector said the project had raised the profile of the often forgotten disease and the detrimental impact it was having on the UK industry.

The report by Dr Tucker and his team was a practical step in the right direction and had at least identified ways to try and prevent future losses. At the same time, it raised several new questions that needed answering to prevent further damage to the industry.

Dr Tucker and the BPEX Knowledge Transfer Team will be taking this report out to producers and processors across the country to drum home the messages it offers to help them start reducing the losses caused by pleurisy in pigs.

©