More awareness of mycotoxins- Part 5. The final weapon in the fight against mycotoxins

Mycotoxins are now known to be a major menace to animal health and production. However, because of the toxin’s chemical characteristics, it is impossible to set up a quality control system that can guarantee their absence in feed materials. The last edition focuses on how to prevent and limit mycotoxin presence in feed.

By Prof Peter Spring, Swiss College of Agriculture and Dr Jules Taylor-Pickard, global Mycosorb manager, Alltech

Limiting exposure risks to animals requires a two-pronged approach:

Minimising the risk and level of mycotoxin exposure of animals ingesting contaminated feed;

Minimising the damage that any remaining mycotoxins may cause to the animal.

Mycotoxicosis causes significant performance and economic losses in pig and poultry production, and taking proper measures to control toxin exposure is essential in maintaining cost-effective production. Mycotoxins have been linked to decreased animal welfare, as many of them lead to disease, compromised immunity and unnecessary suffering. In many western countries, welfare is a major political and consumer concern, and can impact sales of animal products.

Control from field to feed

In order to effectively control mycotoxicosis, it is necessary to understand how toxins are produced and the patterns of fungal growth within feedstuffs. The large diversity of mycotoxins, points of fungal entry and toxin contamination and methods of mycotoxin formation in the feed and food chain result in complexities which cannot be totally controlled. Consequently, control systems need to be focused on individual aspects and areas which can be adequately managed.

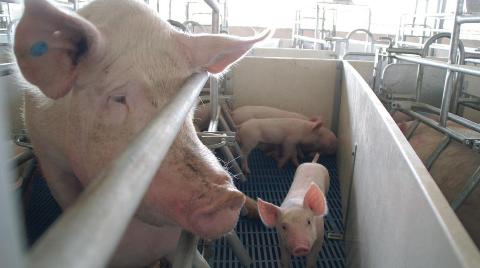

Eliminating the mycotoxin pressure from animal feed can substantially increase sow reproductive performance

Successful control systems start with good farm management during crop production. Scientific and commercial data show that the method of cropping (e.g. limiting plant residues on the surface), crop rotation and genetics have a dramatic effect on mycotoxin contamination levels at harvest. Addressing key control points in the crop production chain will affect the potential for contamination in resulting feed materials. Routine analyses, with frequency of testing based on risk assessment of fungal growth, are a must. As mycotoxins are not evenly distributed within batches of feedstuffs, correct sampling protocols must be followed rigorously. Feed material cleaning can be used to reduce external contamination, e.g. on the hulls of crops and nuts.

However, the waste material from the cleaning process, in which mycotoxins are more concentrated, must be removed from the feed chain, and destroyed in a manner that will not cause further contamination spread. Targeting higher risk ingredients to species known to have a lower sensitivity to potential toxins these contain and setting maximal inclusion levels for single ingredients can further help control the impact of contamination.

Control in feed materials

Mycotoxin production in stored feed materials can effectively be minimised with regular cleaning, control of moisture and temperature in the bins and limiting the time the feed is stored. Typically, standards of feed material cleaning and storage are less thorough on farm than in the feed mill. Hence, it is important that any feedstuffs on farm be assessed and analysed before purchase, to limit potential introduction of toxins.

Despite extensive control measures, animals cannot be entirely protected against exposure to mycotoxins, as it is not possible to totally eliminate them from feedstuffs. Compounded feed, raw materials, micro ingredients as well as bedding are all potential sources of contamination. As many mycotoxins act as immune suppressors, they enhance the risk of disease developing post-infection exposure. Suitable management and husbandry practises to maximise animal health, in combination with the use of proven mycotoxin binders will limit the impact of mycotoxins being absorbed into the tissues of the animals.

Mycotoxin binders adsorb the toxin on their surface and so drastically limit its contact and damage within the animal, leaving it to be excreted in its bound form. When assessing which binder to use it is important to remember that there is only one true and totally reliable test for a mycotoxin binder: It has to be shown to be effective in the animal (in vivo).Underlying data such as mode of action, stability data, and effective in vitro binding under conditions simulating the digestive system are useful, but cannot replace in vivodata. A major challenge for any mycotoxin binding product is to provide high affinity (fast attachment) against a range of toxins, as these are typically present in combination and work together to cause damage in the animal.

Gilt susceptibility

In swine production, gilts are particularly susceptible to mycotoxins as they are under metabolic, social (regrouping) and environmental stress. Prof Trevor Smith and his co-workers at Guelph University exposed gilts during the last three weeks before farrowing (from day 91 of gestation) to deoxynivalenol (DON) (5.5 ppm), 15-acetyl DON (0.5 ppm) and zearalenone (ZEA) (0.3 ppm) and observed a significant drop in reproductive performance which could be eliminated by adding a ß-glucan-based product (GMA, manufactured by Alltech) to the contaminated diet (Table 1). Litter quality was significantly improved by rising the percentage of piglets born alive from 80.7 to 95.4%.

Several trials have investigated the reversion of metabolic changes caused by DON and ZEA (Table 2). The ß-glucan-based product has been shown to reduce hyper-oestrogenism caused by ZEA and to normalise the changes in protein metabolism caused by DON, which is known to inhibit protein synthesis. By limiting these negative impacts, improvements in performance have been reported in several trials using mycotoxin challenge.

Controlling the negative effects of mycotoxins on the immune defence to protect animal health is very important in today’s production and consumer perception environment.

Hidden thief

Some of the biggest health challenges the swine industry is facing are from multi-factorial diseases such as PMWS. John Gadd (2008) commented that “weaner pigs are most at risk from the ‘hidden thief’ of mycotoxicosis and that a mycotoxin binder feed additive does pay.”

Due to physiological status, especially differences in liver metabolism, the effects of mycotoxins can differ between species. In this respect, pigs are most at risk from trichothecenes and aflatoxins. Combinations of more moderate concentrations of different mycotoxins, which individually may appear to be too low in level to be a concern, can act in synergy causing cumulative toxicosis, which affect the ability of the pigs to fight disease and thus affect performance. As it is often difficult to predict which mycotoxin will strike next, it is important to use a mycotoxin binder that has been proven to be effective against a wide range of mycotoxins, maximising protection.

Published data and commercial experience show that mycotoxin binders can significantly reduce the negative impact of mycotoxins. However, in particular when the challenge levels are high or multiple toxins are present, the negative impact cannot be totally avoided.

The use of a binder should not be viewed as a replacement for preventative and quality control measures to limit contamination of feed materials in animal diets. Rather, mycotoxin binders should be applied as an insurance, or second line of defence to limit exposure to toxins in animals.

Source: Pig Progress Volume 25 nr 8